Summary: This paper introduces the application of INVT GD5000 series medium-voltage four-quadrant vector VFD in the inclined shaft hoist of GUANG HANH coal mine plant in Vietnam, analyzes the control strategy after the transformation and describes the effect of frequency conversion transformation.

Keywords: GD5000, Four-quadrant, Medium-voltage vector Variable-frequency Drive, GUANG HANH coal mine hoist

I.Introduction

Mine winch hoist is the main tool used to send the track train to the designated position for underground and external transmission. Hoist is installed on the ground, with the help of steel wire rope to drive train along the shaft slope road. It is used for inclined shaft lifting coal, lifting personnel, transmission materials, tools and equipment.

The main requirements of coal mine hoist are acceleration and deceleration, smooth and stable operation process, and accurate stop position. Working characteristics are slow start speed and high torque.

II. Original Drive Control System Analysis

Before the reconstruction of GUANG HANH coal mine, the old series resistance method was used to realize the control of positive and negative rotation and the regulation of speed. However, there are the following disadvantages:

1. Poor smoothness of speed regulation. Speed regulation by series resistance enables the hoist to consume most energy consumption on series resistance during start-up and speed regulation. The control mode of series resistance is unable to achieve smooth speed control in speed regulation, which leads to hard contact of the instrument when the speed of the whole lifting system changes, which reduces the service life of the system and increases maintenance cost.

2. Low control accuracy and small speed adjustment range. By adjusting the external resistance of rotor to change the speed, the control mode of series resistance cannot achieve a large speed adjustment range due to the influence of resistance. Therefore, higher requirements are required for the precision of limit and braking system to prevent accidents such as offside.

3. Not only the energy loss is high, but also the input voltage fluctuation has a great influence on the speed. The control mode of series resistance enables the resistance to consume energy to achieve the speed control. The slower the speed, the more energy is wasted.

4. lack of stability, Under the influence of the old control mode of the system, the output torque is directly proportional to the speed when the output power is certain, so the speed changes with the load.

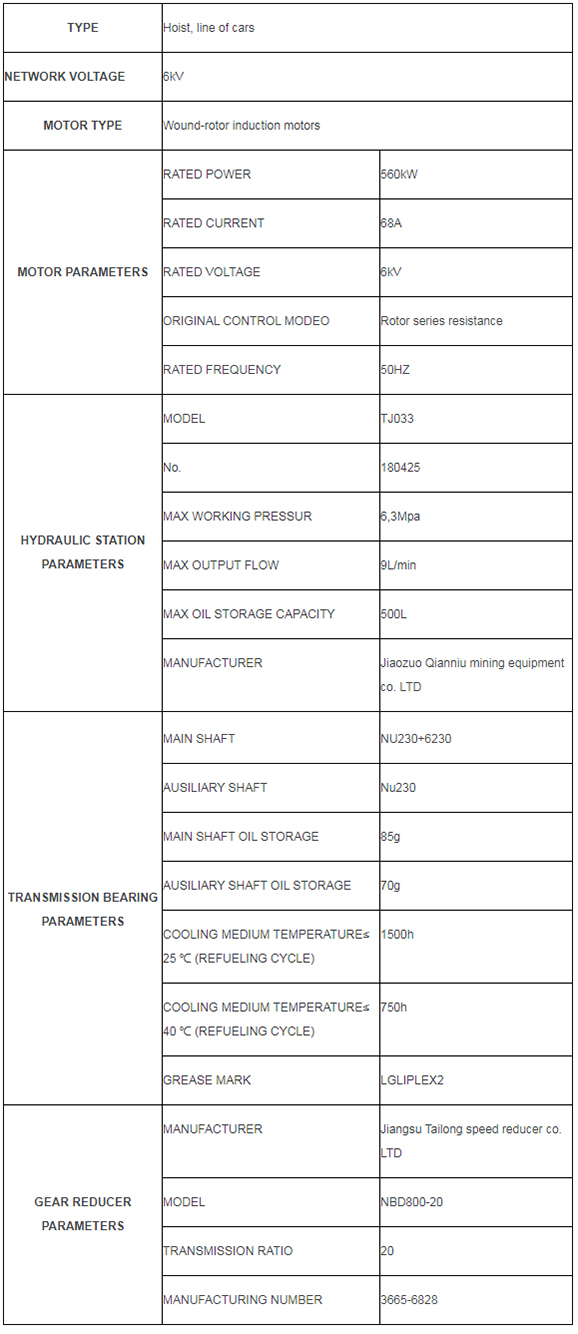

Field load parameter list

Project load photo

III. Project Reform

VFD Selection

| No. | Name | Model | Remark |

| 1 | Four quadrant MVD | GD5000-A0900-06-SR | |

| 2 | Manual bypass cabinet | GD5000-MS |

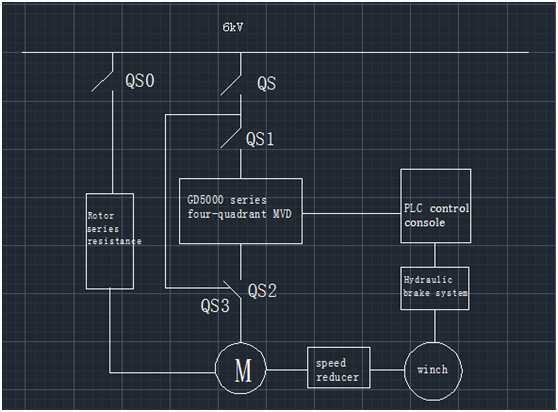

The project adopts a set of GD5000 series four-quadrant MVD independently developed and produced by Shenzhen INVT Electric Co., Ltd. To transform the old control and drive system, keep the original brake system and PLC control console with the new MVD. The MVD is a medium voltage variable frequency speed regulating device of vector control four-quadrant H bridge series multi-level technology. The original old system can still be used at present, so it will not be dismantled temporarily, and will be reserved as the backup system.

The system is equipped with manual bypass cabinet independently produced and developed by INVT. If the VFD needs to be maintained or fails, the bypass cabinet can realize power-frequency bypass to ensure that the load does not stop.

Control mode after modification

IV. VFD Principle

INVT GD5000 series VFD is a high-tech energy-saving product, which adopts advanced IGBT power unit multi-level technology, digital control technology and SPWM pulse width modulation technology. It has the advantages of high power factor, high efficiency, energy saving, high stability, etc, and has the rated power energy feedback ability.

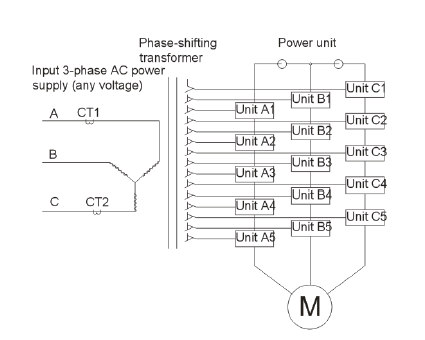

Each phase of the VFD is composed of five power units in series, and the three-phase Y is connected to the output. The output adopts the SPWM wave superimposed by 5 power units of each phase to form high-quality output waveform, which is supplied to the motor to drive the hoist.

Optical fiber communication is adopted between control cabinet, power unit cabinet, transformer cabinet and bypass cabinet to prevent electromagnetic interference. Achieve complete isolation of high and low voltage, improve safety.

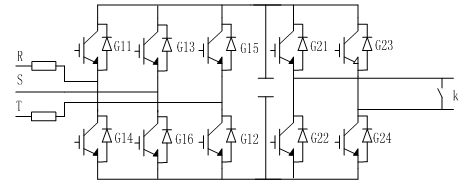

The input side of the power unit is composed of fuse, rectifier and filter parts, and the rectifier part is composed of six IGBT. The inverter consists of four IGBT H bridge inverter outputs, and the motor is driven by the unit series.

Power unit topology

Topology of VFD system

V. Application Advantages

High reliability, The GD5000 series inverters of INVT have perfect protection functions, such as overcurrent, overvoltage, overload, stall and other protection functions.

Small start-up current is small, The impact current in the process of starting and accelerating is small, and the maximum starting current in the process of accelerating does not exceed 1.9 times of the rated current. The hoist increases from the low speed to the highest speed under the heavy load, and there is no large current in the process, which greatly reduces the interference of the load on the power grid.

Wide range of speed regulation, VFD system belongs to the stepless speed regulation, the motor control in the process of acceleration and deceleration is stable, The speed regulation is soft.

Energy saving space is large. As a kind of lifting VFD, the fundamental problem of INVT GD5000 series four-quadrant VFD is to deal with the feedback energy. Because the load is lowering the weight, fast deceleration and emergency stop, so that the motor generated regenerated electromotive force, there will be a greater energy back to the VFD. The VFD use the energy feedback power unit, which can send the energy back to the power grid to achieve energy saving effect. and the VFD output linear, direct voltage regulation, frequency regulation, speed regulation, saving the equivalent of the old system rotor resistance energy consumption.

Production efficiency is high, the stability of the INVT GD5000 series VFD is high, and the speed does not change with the change of the load, to ensure the efficiency of the hoist is not affected by the load. The VFD can control the motor to run stably at a given speed, speed, position, lifting signal, the main order and other peripheral links, can achieve automatic control.

Support power frequency and frequency conversion switching function, support power frequency conversion switching, when the VFD failure or need to maintain, can be switched to the mode of power frequency operation. Power frequency can use the old system to drive the operation, do not delay production.

Photos of the converter in operation

VI. Complimentary Close

The practice has proved that the elevator in coal mine runs well after the technical transformation of VFD, the energy consumption of the elevator is reduced, the lifting capacity of the elevator is increased, and the power factor of the power grid is also improved. Facts have proved that the Medium Voltage VFD has superior product performance, in the coal industry in the energy saving transformation application can create huge economic benefits, in the energy saving and environmental protection has played an important role. It can completely replace the traditional control mode and has very high promotion value.

Reference:

[1] GD5000 Series High-voltage Variable Frequency Speed Control System Manual. Shenzhen Invt Electric CO., LTD.

Nuestro sitio utiliza cookies para brindarle una mejor experiencia en el sitio. Al continuar navegando por el sitio, acepta nuestro uso de cookies de acuerdo con nuestra Política de cookies.