INVT products are much more reliable and professional than other VFD manufacturers, due to INVT support VFDs and service in the sugar industry for more than 10 years. INVT can support not only VFD devices but also control cabinet and display devices which are very convenient for customers.

Through this paper introducing INVT LV(Low Voltage) and MV(Medium Voltage) VFDs and rated solutions applied to different loads in details in the sugar industry to illustrate the economy and practicality by using VFD.

Sugar manufactures are facing major challenges and opportunities:

Challenges:

Old existing driving systems

For a lot of sugar manufacturers, their existing turbine driving technology and devices or DC driving systems are very old and outmoded.

Huge power consumption

Plenty of asynchronous motors are used in sugar factory. If sugar factories use power frequency directly to drive these motors, there will be huge power consumption.

High maintenance cost

Due to those old devices, each sugar-cane milling finishing period needs manufacturers to spend high cost for maintenance.

Hard automation control

As modern control technology developed, many automation control technologies are used in sugar factories. Old devices are hard to be compatible with control systems.

Opportunities:

Sale electricity and bring in income

Many governments are encouraging sugar factory build power plant by burning bagasse to sale electricity to the government.

Innovation brought by the asynchronous motor and it’s driving technology development

As the asynchronous motor and variable frequency drive technology developed, VFD and the asynchronous motor are the perfect combinations. VFD can make asynchronous motor running at optimum condition.

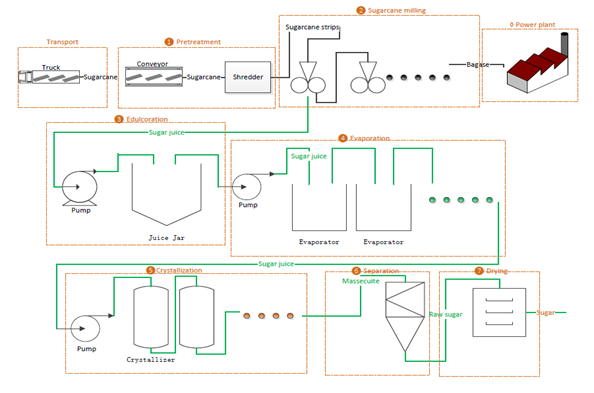

Sugar industry process:

Pig.1 Whole sugar product process flow diagram

INVT VFD applications in each process:

1.Pretreatment

-Shredder

-Conveyor

2.Crystallization

- Pump

- Conveyor

3.Edulcoration

- Pump

- Juice Filter

4.Evaporation

- Pump

- Conveyor

5.Sugarcane milling

- Feeder

- Milling

- Hoister

- Bagasse filter

- Pump

6.Separation

-Continuous centrifuge

-Conveyor

-Scraper centrifuge

7.Drying

-Conveyor

-Hoist

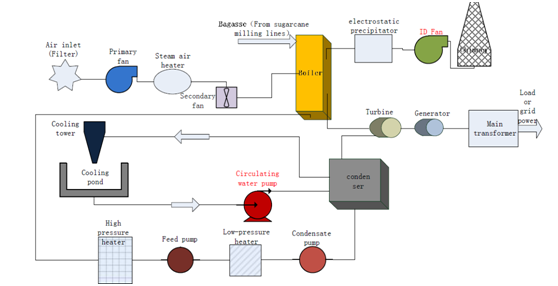

8.Owned power plant

-Fan

-Pump

Sugar factory power plant process:

Pig.2 Power plant process flow diagram

Benefits of variable speed drives:Variable frequency drive

Highlight

Increase sugar extraction; In the pretreatment and sugarcane milling process using VFD, can increase sugar extraction at least 0.1%.

Lower power consumption and energy saving, for example, sugarcane milling using VFD the energy saving ratio is more than 15% and pump energy saving ratio is more than 30% by using VFD.

Increased process reliability.

Minimal wear and tear of equipment.

Soft starting.

Flow and pressure control.

Fast and precise process control.

Reduced maintenance costs and longer lifetime of the equipment.

Educed CO2 emissions.

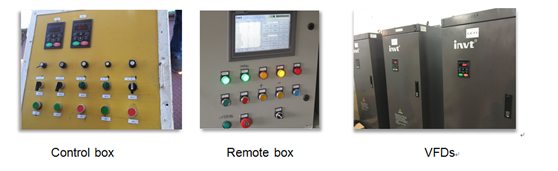

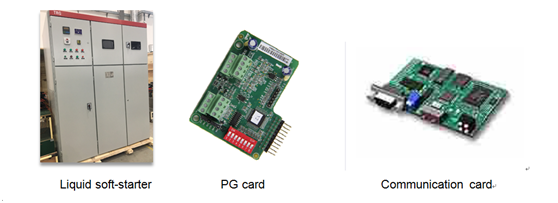

INVT support diversified configuration

For the sugar industry, INVT can support not only VFD but also control unit/cabinet, liquid soft-starter, distribution panels and plenty of communication cards.

INVT support systems include:

-Control box

-VFD cabinet

-Variable frequency drive

-Liquid soft-starter

-Modbus/Profibus/Ethernet communication protocol

-INVT-Studio PC monitoring tool

Nuestro sitio utiliza cookies para brindarle una mejor experiencia en el sitio. Al continuar navegando por el sitio, acepta nuestro uso de cookies de acuerdo con nuestra Política de cookies.