A glow-wire test is suitable for fire hazard tests of electrical and electronic products, household appliances and their internal combustible materials. It simulates a scenario where an ignition source, such as a heated element or an overloading resistor, causes the combustible materials nearby to ignite and flame spread in a short time, resulting in the burning of insulating materials or other solid combustible materials.

The test is conducted to determine the ignition hazard of electrical and electronic equipment, and the flammability, glow-wire ignition temperature (GWIT), and glow-wire flammability index (GWFI) of solid insulating materials and other solid combustible materials by heating the heater wire of specified material and shape to the test temperature with high current for a specified period of time, then scalding the test specimen vertically with specified pressure for a certain period of time, and observing whether the specimen and the bedding object ignites or the burning time.

If a product uses unqualified combustible materials in the production process, there would be a high fire risk of these materials due to various reasons when the device is running. Therefore, the glow-wire test of materials is necessary for quality control. The following conditions may cause combustible materials to catch fire:

1. When the device is powered on and the live connection parts are in poor contact, the combustible materials may catch fire.

2. When the device is powered on and the temperature of internal components rises too high, the combustible materials supporting it may catch fire.

Test standard: IEC 60695-2-10, IEC 60695-2-13, GB/ T 5169.10, GB/T 5169.13 are commonly used.

Test conditions: The glow-wire test is divided into steps such as pretreatment, documentation of the test process and determination of the results, as detailed below.

1. Specimen pretreatment and experimental environment:

Condition the pine board and wrapping tissue for 24h at 15–35℃ and at a relative humidity between 45% and 75%.

Condition a specimen with a length ≥ 60mm, a width ≥ 60mm, and a preferred thickness of (0.75±0.1)mm, (1.5±0.1)mm, (3.05±0.2)mm for 48h at 23±2℃ and at a relative humidity between 45% and 75%.

The test shall be completed within 30 min after the pretreatment under the standard testing environment.

2. Test process recording:

a) Mount or clamp the specimen with the flat test surface vertical and the tip of the glow-wire centered on the specimen surface.

b) Place the gift wrapping tissue/wooden board at a distance of 200mm±5mm below the place where the glow-wire applied to the specimen.

c) Heat the glow-wire to the specified temperature. Ensure that this temperature is constany within 5K for a period of at least 60s, the glow-wire is at least 5.0mm away from the specimen, and no futher adjustment to the heating current or voltage is to be made until the test is completed.

d) The tip of the glow-wire is brought slowly into contact with the specimen for 30s±1s. An approximate rate of approach and withdrawal would be 10mm/s to 25mm/s. However, the rate of approach shall be reduced to zero upon contact to advoid forces of impact exceeding 1.0N ± 0.2N. and the contact time of 30s ± 1s. Then the head shall leave at the same rate. If an ignition occurs, the time tE from the start of the flame to its extinction shall be recorded. The penetration of the tip of the glow-wire into and through the specimen shall be limited to 7 mm ± 0.5 mm.

3. Test criteria:

a) There is no ignition, or

b) the flames or glowing of the specimen extinguish within 30s after removal of the glow-wire and there is no ignition of the wrapping tissue.

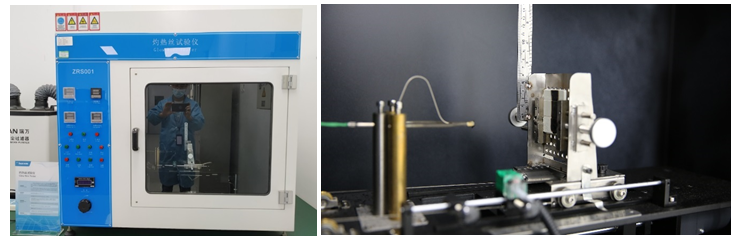

Test equipment:

INVT is equipped with glow-wire tester, which can be used for the combustible materials on devices, single boards, complete machines and other products. The main parameters of the tester are as follows:

Heating temperature: ambient temperature–1000℃

Glow-wire specification: 4mm diameter (with 80% of nickel and 20% of chromium). Made in a standard size.

Force of glow-wire to specimen: 1±0.2N

Pressed depth: 7 mm±0.5mm

Speed: 10–25mm/s

Distance from tissue to flame: 200±5mm

Product improvement:

Enables rapid testing of the flammability of combustible materials on electronic products and improves product reliability.

Facebook

Facebook

Twitter

Twitter

Google+

Google+

LinkedIn

LinkedIn