Drive products operate with high voltage. To avoid exposure of live internal components, a shell should be designed with a certain level of protection. The common protection levels are IP20, IP54, and IP67. The shell can protect the equipment from some external influences and prevent direct contact with live parts from any direction, and to prevent or restrict foreign objects from entering the product unless a key or tool is used.

In normal use, the shell usually provides good protection. However, there may be external forces such as stepping, stacking, squeezing, and collision during installation and maintenance, which may lead to deformation of the shell, risk of lowering the protection level of the product, or even directly cause the shell to rupture or the concave shell to touch the charged part and lead to danger. Therefore, the compression strength of the shell needs to be restricted to a certain extent, so that the protection level will not be affected when it bears the specified unexpected pressure. Especially for products with a protection level of IP67, sealing is not guaranteed once the shell is significantly deformed.

During the product development process, shell compressive strength testing is required to observe the deformation of the shell and the change of protection level before and after the test to improve the safety protection ability of the product against external forces.

Test method: apply rated uniform pressure to each surface of the sample using a shell compression tester and record the deformation. Compare whether the protection level drops before and after the test.

Test standard: GB/T 24347, GB/T 18488.1.

Test conditions: There are two kinds of test condition in general:

1) Applied surface: each surface of the shell

Applied area: any area of 30cm×30cm

Applied force: uniformly apply the force equivalent to a mass of 100kg

Criteria: There shall be no obvious plastic deformation on the shell surface and the level of protection shall not be reduced after the test.

2) Applied surface: in 3 directions of the shell

Applied area: not less than 5cm×5cm

Applied force: slowly apply 10kPa pressure

Criteria: The plastic case should not be deformed significantly and the level of protection shall not be reduced after the test.

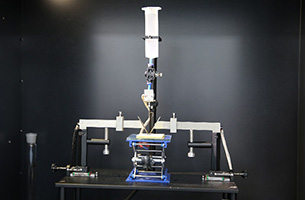

Test equipment: Shell compression tester, mainly used to test the mechanical strength of the sample shell by applying a predetermined load until the sample shell is damaged or reaches a predetermined displacement value. The tester has a maximum load of 5kN, with high force accuracy and good stability. It is equipped with various sizes of fixtures, which can meet the compressive strength test requirements of our existing products.

Facebook

Facebook

Twitter

Twitter

Google+

Google+

LinkedIn

LinkedIn

Prev

Prev