To better simulate the industrial control products (such as VFDs) subjected to oil pollution in the working environment in the chemical industry, mining, machine tools processing industries, and verify their electrical performance, insulation strength, and corrosion resistance, INVT has formulated corresponding test specifications and developed a special oil pollution test equipment box to improve product quality in a targeted manner.

In the chemical, mining, and machining industries, oil, water, and corrosive gases often drip and adhere to industrial control products. Oil stains mainly appear in the machining industry and its formation is mainly due to two mechanisms: atomization and evaporation. The atomization is mainly caused by the fierce impact of the metal lubricating liquid on the fixed and rotating units in the machine tool system and the small droplets are formed floating in the working environment. The diameter of the droplets is generally 2um~10um. Evaporation refers to the process in which the cutting fluid absorbs heat during the metal cutting and grinding process and the liquid temperature rises to the boiling point to produce small gaseous particles. The particle size is usually 2um or less. Studies have shown that 95% of the oil mist droplets in the atmosphere in the workshop are less than 3um in diameter. In the mining, chemical, and other industries, there may even be water dripping and oil dripping.

Reference standard: GB/T 23574-2009.

Failure mode: The oil stains remaining on the circuit board or the shell, which usually bind the conductive dust in the air and absorb water vapor, corrode various parts, and reduce their insulation performance, shortening the effective service lifetime of the product. The following failure modes usually occur:

1.The pins of circuit board components are oxidized, and screws, connectors, and various terminals are corroded.

2.There are obvious water or oil stains on the circuit board or between the device pins.

3.There are abnormalities such as failure to start normally or delayed start, abnormal keyboard display, no response to keystrokes.

4.A fault is reported during operation and the fault cannot be reset.

5.The decrease of insulation resistance leads to the phenomenon of sparking and arcing.

6.Performance degradation or other problems that do not meet the requirements of the specification.

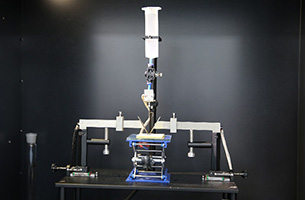

Test equipment: The oil pollution test chamber is a non-standard test chamber developed by INVT to simulate the harsh oil pollution environment in the market. It is embedded with our industrial control products (HMI, VFD, PLC), designed and debugged by our in-house R&D staff. Considering different working conditions, we have formulated corporate test specifications, which can effectively simulate the harsh oily environment where the product is actually located, and identify product defects and weaknesses for improvement and correction.

Facebook

Facebook

Twitter

Twitter

Google+

Google+

LinkedIn

LinkedIn

Prev

Prev