A dielectric withstand test is performed to verify that the gap between the components and the assembled product and the solid insulation have sufficient dielectric strength to withstand overvoltage conditions. It is commonly used to verify the ability of electrical appliances, electrical equipment, electrical installations, electrical circuits, and electrical safety appliances to withstand overvoltage. The test can be divided into power-frequency withstand voltage test and DC withstand voltage test.

1. The test voltage of the power-frequency withstand voltage test is one to multiple of the rated voltage of the tested device and is not less than 1000V. Apply voltage for:

1) 1 minute for equipment with porcelain and liquid as the main insulation.

2) 5 minutes for equipment with organic solids as the main insulation.

3) 3 minutes for the voltage transformer.

4) 10 minutes for oil-immersed cables.

2. In the DC withstand voltage test, the leakage current-voltage characteristic curve can be drawn with the value of the leakage current at different test voltages.

It is common that the electrical gaps and solid insulation of the product are sufficient to withstand overvoltage during installation and use. When the equipment is energized, the internal electrical gaps and solid insulating materials should be subjected to sufficient dielectric strength to ensure the normal operation of the equipment and to prevent users from being shocked. The dielectric strength tests should be conducted for the following insulating materials and harsh conditions.

1. Components and insulating materials in electrical equipment

2. Insulation of electrically conductive objects in electrical equipment

3. Partial or total exposure of the insulation to moisture

4. Serious deterioration of the insulating oil and serious aging of the insulating material

Test standard: IEC/EN/UL 61800-5-1, GB 12668.501, IEC 60950, and GB/T 16927 are commonly used.

Test conditions: The test dielectric strength value is related to the rated voltage of the product. Generally, the test will last for 1 min.

| Product rated voltage (V) | AC/ DC Dielectric Withstand Test (V) | |||

| Electricity to PE | Electricity to user terminal | |||

| AC | DC | AC | DC | |

| 220 (Three phase) | 1350 | 1910 | 2700 | 3820 |

| 220 (Single phase) | 1500 | 2120 | 3000 | 4240 |

| 380 | 1500 | 2120 | 3000 | 4240 |

| 525 | 1800 | 2550 | 3600 | 5090 |

| 590 | 1800 | 2550 | 3600 | 5090 |

| 660 | 1800 | 2550 | 3600 | 5090 |

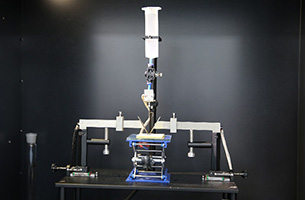

Test equipment:

Pulse voltage generator, available for devices, single boards, complete machines, and other products, covering almost all INVT products.

1.Output voltage range: 0-50kVac±5%

2.Leakage current test range: 1-100mA±5%

3.Alarm value error: 1-100mA±5%

4.Impedance: 2-500Ω±10%

Product improvement:

1.Physical effects: Verify whether the insulating material can be broken down.

2.Piezoelectric effect: Enables rapid testing of the reliability of the internal gaps and insulating materials of electronic components or products.

Facebook

Facebook

Twitter

Twitter

Google+

Google+

LinkedIn

LinkedIn

Prev

Prev