A tracking test is to verify the comparative tracking index (CTI) and proof tracking index (PTI) of the solid insulating materials or the solid insulating materials on the selected components, so as to determine the appropriate insulation distance between conductors on solid insulating materials.

If the CTI or PTI values of the solid insulating materials used in a product are not clear, the distance between conductors with voltage differences on the solid insulating material may be insufficient, which will cause the tracking breakdown or fire when the device runs, or the distance may be excessive, increasing the product cost. Therefore, it is important to determine the CTI and PTI of the solid insulating materials.

Test standard: GB/T 4207-2012 and IEC 60112-2003 are commonly used.

Test condition: The tracking test consists of specimen pretreatment of the specification quantity, preparation of the test electrolyte, test process recording, result determination, and other steps.

1. Pre-process the specimen. Prepare at least 5 specimens with a size ≥ 20mmX20mm and the total thickness ≥3mm (You can overlap all specimens to reach the thickness). Pre-process the specimens for at least 24h.

2. Prepare the test electrolyte. Dissolve the analytical anhydrous ammonium chloride (NH4CL) reagent with a mass fraction of about 0.1% and a purity of not less than 99.8% in deionized water with a conductivity of not more than 1mS/m. The test solution has a resistivity of 3.95Ω•m±0.05Ω•m at 23°C±1°C. The solution can also be prepared based on the conductivity. The conductivity range should be 2500-2566 uS/cm.

3. Record the test process.

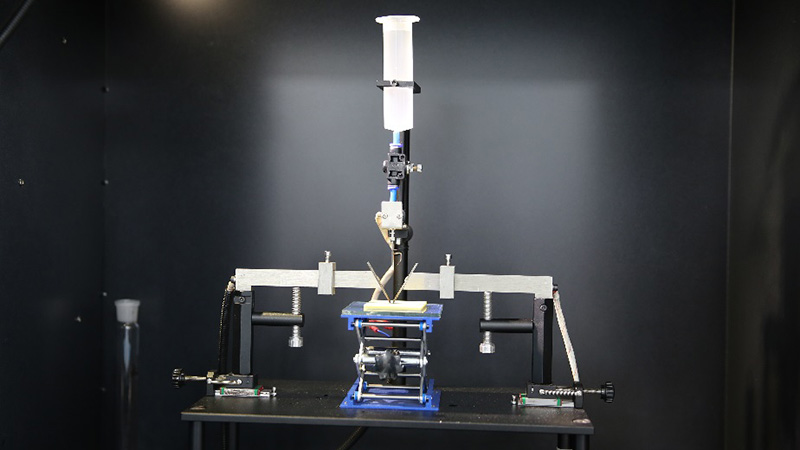

1)Adjust the distance and angle of the two electrodes, and align the dropper needle with the center of the gauge.

2)Adjust the position of the counterweight slider of the electrode fixing mounting arm so that the pressure applied to the specimen remains constant throughout the test.

3)Adjust the height of the dropper so that the distance between the dropper needle and the item to be tested is 30-40mm.

4)Set the time interval of dripping to 30±5S and the drip count to 50. Wipe the drip needle and drain 5-20 drops of solution to ensure the accuracy of the concentration of the droplet solution.

5)Adjust the droplet size. The mass of 50 consecutive drops should be 0.997g-1.147g and the mass of 20 consecutive drops should be 0.380g-0.480g.

6)Set the alarm current of the droplet short-circuits to 0.5A and set the test voltage to 175V.

7)Place the tested item on the glass support frame to start the test, record the test phenomenon and test time, and count 50 drops.

8)Select other 4 different points on the tested item and repeat the test 4 times, that is, the test should be conducted on 5 specimens or 5 positions on one specimen.

9)If the sample passes the 175V voltage test, increase the test voltage by 25V and test the 5 specimens again.

4. Test criteria:

The 5 specimens should be able to withstand 50 drops of solution under the maximum withstand voltage index without tracking failure for at least 25s. When the current exceeds 0.5A, there is no burning that lasts for more than 2s. In this case, the tested materials are qualified.

Test equipment:

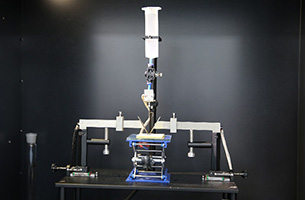

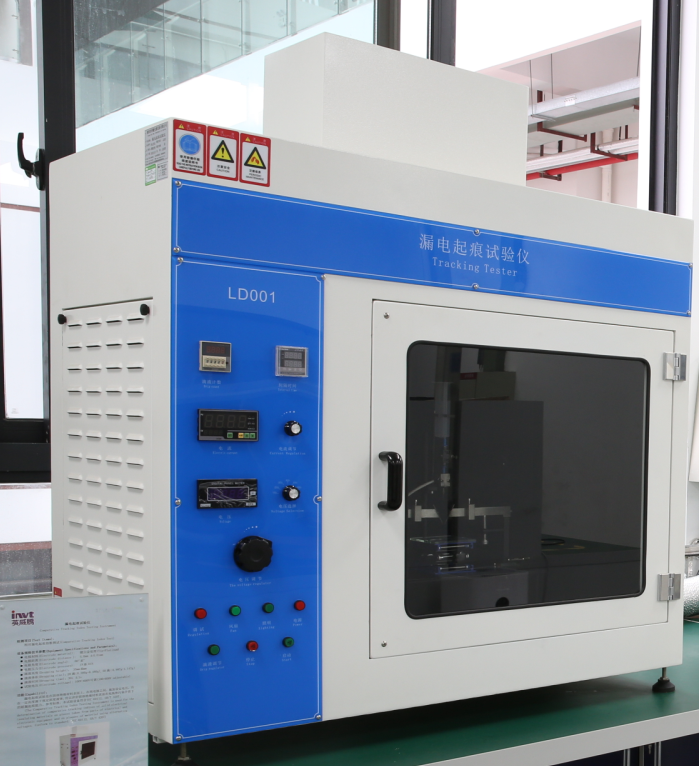

INVT is equipped with tracking test apparatus, which can be used for the solid insulting materials on devices, single boards, complete machines and other products, covering all our solid insulating materials. The main parameters of the tester are as follows:

Electrode materials: Platinum-plated treatment

Electrode distance: 4.0mm±0.01mm

Electrode angle: 60°± 5°

Electrode pressure: 1N±0.01N

Droplet height: 35mm±5mm

Dripping time: 30s±1s

Test voltage: 100V—600V, adjustable

Product improvement:

Enables rapid testing of the CTI and PTI values of solid insulating materials on electronic products and improves product reliability.

Facebook

Facebook

Twitter

Twitter

Google+

Google+

LinkedIn

LinkedIn

Prev

Prev