Salt mist test is a kind of environmental test to evaluate the corrosion resistance of products or metal materials by using the artificial simulated salt mist environment created by the salt mist test equipment. Salt can degrade the performance of parts manufactured using metallic and/or non-metallic materials. The mechanism of salt corrosion in metallic materials is electrochemical, whereas the degradation effects experienced on non-metallic materials are caused by complex chemical reactions of the salt with the materials involved. The rate at which corrosive action takes place is dependent, to a large extent, on the supply of oxygenated salt solution to the surface of the test specimen, the temperature of the specimen, and temperature and humidity of the environment.

The test standard clearly and specifically stipulates the salt spray test conditions, such as temperature, humidity, and concentration and pH value of sodium chloride solution. In addition, the test standard also stipulates the performance of the salt spray test chamber in the aspect of technology. The judgment methods of salt spray test results include rating judgment method, weighing judgment method, corrosion occurrence judgment method, and corrosion data statistical analysis method. The corrosion resistance of the product is evaluated through the test.

Test standards: GB/T 2423.17, GB/T 2423.18, IEC 60068-2-11, and IEC 60068-2-52 are commonly used.

Test conditions: There are many details in the salt spray test, and acid, alkali, salt and water used in the test are clearly stipulated. For example, if it is required to use distilled water or deionized water, the content of the sodium iodide in salt shall be less than or equal to 0.1%, and the total impurity content shall be less than or equal to 0.3%.

1) Neutral salt spray test: Temperature in the chamber: (35 ±2) ℃/Salt solution concentration mass ratio: (5 ±1)%/Spray settlement: 1–2mL/ h·80cm2/Salt solution pH: 6.5–7.2/Test time: 16 h, 24 h, 48 h, 96 h, 168 h.

2) Cyclic salt spray test: The test conditions are as follows;

Test category: It can be divided into neutral salt spray test, acetic acid salt spray test, copper accelerated acetic acid salt spray test, and cyclic salt spray test.

1) Neutral salt spray test (NSS test) is the earliest and most widely used method of accelerated corrosion test at present. It uses 5% NaCI solution, and the pH value of the solution is in the neutral range (6–7) for spraying. The test temperature is 35 ℃, and the sedimentation rate of salt spray is between 1–2ml/80cm²·h.

2) Acetic acid salt spray test (ASS test) is developed based on the neutral salt spray test. It is to add some glacial acetic acid in 5% NaCI solution, so that the pH value of the solution is reduced to about 3, the solution turns acidic, and salt spray finally formed is changed from neutral to acidic. Its corrosion rate is about 3 times faster than that of NSS test.

3) Copper accelerated acetic acid salt spray test (CASS test) is a kind of rapid salt spray corrosion test which is recently developed abroad. The test temperature is 50 ℃. Add a small amount of copper salt-copper chloride to the salt solution to strongly induce corrosion. Its corrosion rate is about 8 times as much as that of the NSS test.

4) Cyclic salt spray test is a comprehensive salt spray test, which is actually a combination of a neutral salt spray test plus a constant damp-heat test. It is mainly used for cavity-type machine products, through the penetration of the tidal environment, salt spray corrosion occurs not only on the surface of the product, but also in the interior of the product. It converts the products alternately under the conditions of salt spray and damp heat environment, and finally evaluates whether the electrical and mechanical properties of the machine have changed or not.

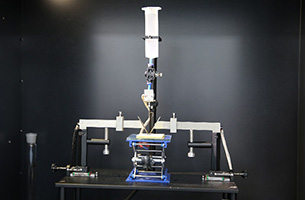

Test equipment:

Due to strong corrosion effect of the salt spray test chamber, the salt spray test chamber is mostly made of PVC board, and its internal connecting parts are mostly bonded with glue.

Our company is equipped with three salt spray test chambers which can be used for performing the salt spray tests mentioned above. Their test conditions and test tolerance fully meet the operating requirements, covering devices, PCBA board, machines, and other products, almost all of our products (excluding cabinets).

Product improvement:

1. Metal structural parts: Perform the incoming inspection for commonly used screws, terminal blocks, copper bars, and connectors to evaluate whether they meet the product operating requirements, and to screen unqualified samples intuitively and quickly.

2. Conformal coatings: Check the coatings such as PCB protective paint to find and improve the process defects such as incomplete coverage, uneven spraying, spray blistering and delamination.

Corrosive IC chip base pin

Facebook

Facebook

Twitter

Twitter

Google+

Google+

LinkedIn

LinkedIn

Prev

Prev