Stacking is usually adopted to make full use of space and transport capacity during the product transportation and storage. However, stacking will cause a surge in the pressure exerting on the goods at the bottom. If in the storage link, cartons softening caused by high ambient humidity may bring about goods collapse; if in the transportation link, the additional stress caused by vibration may squeeze the cartons at any time and damage the contents. Therefore, we will take this case fully into account in the packaging design, and carry out the corresponding packaging stacking test to reduce the damage rate of normal goods storage and transportation.

Like the drop test, the stacking test is also a part of a series of tests for package (such as temperature and humidity storage, vibration, drop, etc.).

Stacking height:

Choose different stacking heights according to different transportation methods of goods:

1. If the height of the general van body is 1.5 m–3.5 m, the stacking height is also 1.5 m–3.5 m.

2. The stacking height of air transportation is generally 1.8 m.

3. The stacking height of the railway transportation is generally 3.5 m;

4. The stacking height of some sea transportation even needs to reach 7.0 m;

If stacking height is chosen according to the storage of the goods, it is generally 3.5 m.

Stacking time: During the actual circulation of goods, the general transit time is 1-7 days, but in some standards, such as ISTA, the time compensation coefficient is used to accelerate the test, and the testing time is shortened to 1h, while in GB/T 4857 series standards, the time is measured in days, at least 1 day.

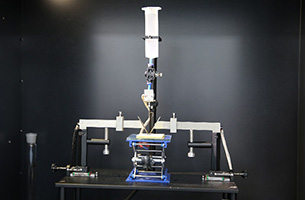

Test standard: The most commonly used are GB/T 4857.3, GB/T 4857.4, ISO 12048, ISTA series, etc. Test equipment: Our stacking test equipment is a packaging compression tester, which can generate a maximum pressure of 49000N, meeting the maximum stacking load of our existing packaging and providing guarantee for packaging design.

Benefits to product improvement:

1. Calculation of the carton compressive strength: The strength of the carton which experiences environmental pretreatment may not have the compressive capacity at the time of design. At this time, when you conduct the stacking test, you can calculate the margin coefficient according to the actual crushing curve so as to ensure the effective strength of the carton.

2. Judgment of the strength of the prototype body shell: During the stacking process, most of the contents body will also play a supporting role, but if the design is unreasonable, the contents shell may be deformed or directly damaged in some serious cases. Therefore, the stacking test is also an indirect judgment on the compression resistance of the contents.

Facebook

Facebook

Twitter

Twitter

Google+

Google+

LinkedIn

LinkedIn

Prev

Prev