Only after products under development pass the performance and reliability tests of respective laboratories, with the product design problems resolved, and with compliance to the related specifications and standards, the products can be mass manufactured. The following focuses on random vibration in reliability test.

We classifies random vibration test into mechanical reliability test. The random vibration test can measure the ability of the sample to resist the dynamic load without unacceptable functional degradation and with conformity to the whole structure under the specified random vibration test environment. It is applicable to products that may suffer random vibration in transportation or working environment.

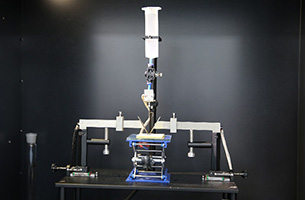

Test equipment: Currently, the main test equipment for random vibration is still electromagnetic vibration machine, which is widely applicable and can meet different product test requirements by designing various clamps. We have 1T and 5T propulsive-force vibration machines, which can adapt to different types of products by using different clamps.

Test standards: Currently, the electronic industry mainly involves GB/T 2423.56, GB/T 4857.23, and IEC 60068-2-4, corresponding to the tests for assembled machines and packaged samples.

Test spectral line: The following figure shows a typical packaged sample transportation spectral line chart, in which the horizontal coordinate represents the frequency range and the vertical coordinate represents the acceleration spectral density. The area enclosed by the curve is the root mean square value of the acceleration. In addition, the test duration is shown. After the input parameters are preset on the computer, the vibration controller controls the power amplifier to drive the moving circle of the electromagnetic vibration machine to make reciprocating motion. One or more acceleration sensors collect the motion acceleration values of the machine and send back to the vibration controller to form a closed-loop control. In this way, the control accuracy is high and the operability is convenient.

What can the random vibration test do for products?

1. You can set the test conditions in a specific use scenario of a product according to the test standards and specifications so that the test can accelerate the fatigue of the product structure. Then you can find the weak points of the design and make continuous improvement after the R&D and design optimization.

2. The test can be used for structural modal simulation comparison in the early stage to correct the simulation error and reduce the test and verification rounds.

3. According to the actual collection road spectrum or relevant standard conditions, the test can simulate the package transportation environment to check the product packaging transportation adaptability and design rationality.

Main impacts on products

1. Packaged products are mainly composed of contents, cushioning materials, protective bags and outer package. Generally, the contents are put into protective bags, surrounded with buffer materials all around, and then placed in the outer packing box. The main impacts of random vibration include:

1) The outer package is damaged, including cracks on the seam edge, carton punctured, and serious deformation

2) Buffering material damage, such as buffering material cracked and permanent deformation

3) The contents are damaged, including internal components or fasteners falling off and surface abrasion

2. Most of assembled products are composed of shell frames, PCBs, and components. Most of these parts are connected by means of fastening, insertion and spot welding, and thus the main impacts of random vibration include:

1) Structural damage

2) Working performance downgrade

3) Process performance downgrade

This is a brief introduction to random vibration. The next part will introduce sweep frequency vibration.

Facebook

Facebook

Twitter

Twitter

Google+

Google+

LinkedIn

LinkedIn

Prev

Prev