A vertical burning test is to check the flame retardant grade and burning characteristics of combustible materials on the product.

If a product uses unqualified flame retardant materials in the production process, these unqualified materials are likely to cause a fire and spread the fire to the outside of the device due to various reasons when the device is running. Therefore, the burning test of materials is necessary for quality control. The following conditions may cause combustible materials to catch fire or fire spreading:

1. When the device is powered on and the live connection parts are in poor contact, the combustible materials may catch fire.

2. When the device is powered on and the temperature of internal components rises too high, the combustible materials supporting it may catch fire.

3. When the device is powered on and the internal circuit is arcing, the combustible materials may be ignited.

4. When the internal combustible materials catch fire, other flame retardant materials cannot inhibit the spread of flame.

Test standard: IEC 60695-11-3, IEC 60695-11-10, ANSI/UL 94, GB/T 5169.16 are commonly used.

Test conditions: The vertical burning test is divided into steps such as pretreatment, documentation of the test process and determination of the results, as detailed below.

1.Specimen pretreatment and experimental environment:

Condition two sets of three strip specimens at a temperature of 23°C ± 2°C and relative humidity of 50% ± 10% for at least 48H. After the specimen is taken out of the conditioning box, the test should be completed within 30 minutes.

Cotton pads should be conditioned in a drying oven for at least 24H before use. It should be used within 30 minutes after being taken out of the drying oven.

2.Standard 50W nominal flame debugging:

a.Place the combustion tube vertically.

b.Press the power button to power up the experimental apparatus.

c.Open the gas tank valve and press the gas solenoid valve button to switch on the test chamber gas.

d.Turn the gas flow knob, gas pressure knob, and the needle valve at the bottom of the combustion tube, and then press the ignition button to ignite the gas.

Adjust the gas flow knob, the gas pressure knob, and the needle valve at the bottom of the combustion tube to achieve a standard 20mm ± 2mm flame and keep it burn for 5mins.

3.Clamping of specimens and location of the combustion tube:

a.Clamp the specimen as required

b.Determine the position of the specimen and the combustion tube.

c.Apply flame and move the vertical support fixture longitudinally.

d.Observe and record.

e.Determine the result.

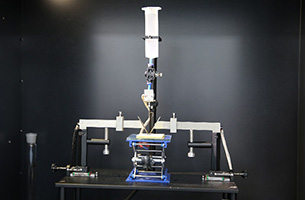

Test equipment:

INVT is equipped with horizontal and vertical burning tester, which can be used for the combustible materials on devices, single boards, complete machines and other products. The main parameters of the tester are as follows:

Chamber volume: 0.5m3

Bunsen burner: 50W

Burning angle: 0°, 20°, 45°

Flame height: 18-20mm (adjustable)

Gas flow: 105±10ml/min

Back pressure: 10mm

Flame temperature time: 100°C±5°C to 700°C±3°C; 44s±2s

Facebook

Facebook

Twitter

Twitter

Google+

Google+

LinkedIn

LinkedIn

Prev

Prev