Abstract:

This paper mainly presents INVT AX series motion controller PLC used with EtherCAT servo driver to make different types of capsules on wood. In this project HMI use for data feeding and monitoring of the process.

Keywords: AX72, EtherCAT servo drive, servo drive, router motor and drive, VS series HMI.

I.Introduction

The major section of this machine’s interpolation, cycle selection, router, servo control etc.

1)Router Motor: Here one AC motor use to control the function of main tool, and continue rotate till command given from PLC.

2)Servo: Here 2 axis servo system used for complete process execution. X-Y axis for linear and arc interpolation logic, z-axis used to provide depth in wood fixed by pneumatic system.

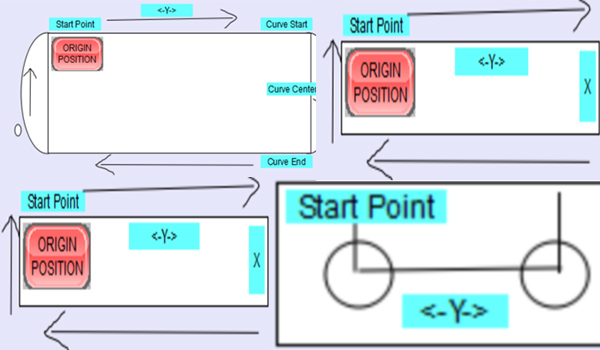

3)Cycle selection: In this machine different type of cycle executed like square, capsule male, capsule female, hole distance cycle and zigzag cycle.

4)Process: Here all cycle tested with different speed as per customer requirements, proper working of arc interpolation logic. As per application interpolation need in only capsule cycle, other cycle work in linear interpolation as well as normal absolute operation.

Table selection : In auto sequence of cycle one table in working state and another table in loading/unloading state. For both table selection function provide and auto, manual as well as semi-auto cycle define in logic as per customer requirements. For different types of jobs, recipe function also added for customer program saving with job name and specification details.

Figure – Different type of cycle

II.Project information and Solution

1. Project information

In this application capsule job made using linear and arc interpolation, absolute system predefines as well as square and other job design in absolute command.

PLC: AX72-C-1608N + VS-070HS + EtherCAT servo with and without brake

Total 2 axis servo system used, X-Y plan

Router motor run through DOL as well as drive option also provide.

Two cylinders use to push job with force when job designing in running state.

AX series motion PLC used Arc interpolation and linear interpolation

VS series HMI use for data setting, monitoring and recipe function purpose.

2. INVT solution

| Product | Model no. | Quantity |

| PLC | AX72-C-1608N | 1 |

| HMI | VS-070HS | 1 |

| Servo | SV-DA200-2R0-4-N0 | 2 |

| Motor | SV-MM13-2R0E-4-9A0/9A2 | 2 |

III.System commissioning

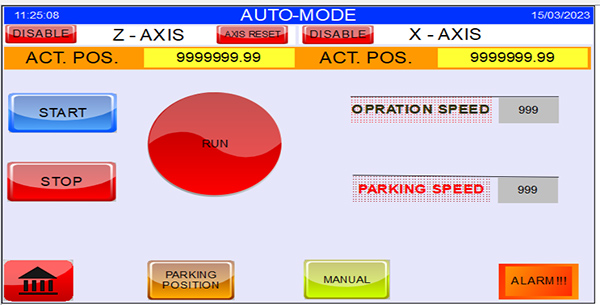

According to the control logic and display requirement, PLC and HMI program are made and uploaded.After commissioning, the system runs steady, products are meet the quality requirement. Site photos are as below:

Figure – AX72 PLC control panel and Back Side view of Machine

Figure - HMI auto cycle window

Figure – Machine side view and front view

Figure – Product image of interpolation curve

IV.Advantages and benefits

In AX PLC we achieved ARC and linear interpolation with easily and smooth operation

This solution is cost effective and easily we can implement where cost issue compares to Delta and Schneider system

Accuracy too much high and speed also maintain as standard

PLC and servo communication over EtherCAT so external wiring decrease and

troubleshooting easily.

V.Conclusion

As per study and application execution, these industries multiple axis type of machines for wood male-female capsule making machine. We achieved result through implementation of simple cost-effective model of AX series PLC. This application very useful for home as well as industrial product manufacturing.

VI.Future Scope

In this application we execute our system with 2 axis, here 2 axis run in interpolation with linear as well as arc interpolation system. These types of application are popular and we provide best solution with minimum price. This type of system we can implement in many industries.

VII.Reference

1.INVT AX series PLC manual and HMI manuals.

2.https://www.invt.com/download

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.