Background

Solventless laminating machine belongs to the post-printing part of the printing industry chain. It is a device used for solventless laminating technology. Its working principle is to compound two or more materials that are insoluble in each other through mechanical force. No need to use solvents. It has the advantages of no need for solvents, high production efficiency, good composite quality, environmental protection, simple operation, convenient maintenance, and long service life.

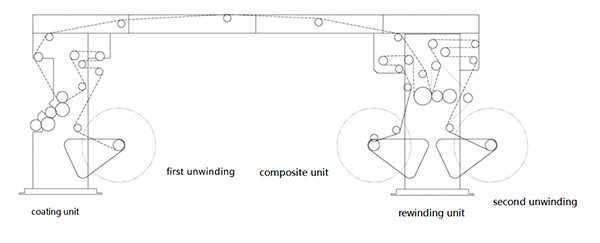

Solventless laminating machines are mostly two-layer laminating and have a single-station rewinding and unwinding structure. Its main components include: first unwinding unit, coating unit, second unwinding unit, composite unit, and rewinding unit.

Client needs

A customer needs to update and upgrade solventless laminating machine equipment due to industry market competition. solventless laminating machine required:

1. The speed range varies greatly, including high-speed winding (1500 rpm) and low-speed operation (6 rpm).

2. The roll diameter can be calculated in real time to achieve tension control.

3. The composite process requires uniform coating, that is, high speed stability requirements and small speed fluctuations are allowed.

4. The control cabinet space is limited, so the driver cannot be installed in a size that is too large.

INVT Solution

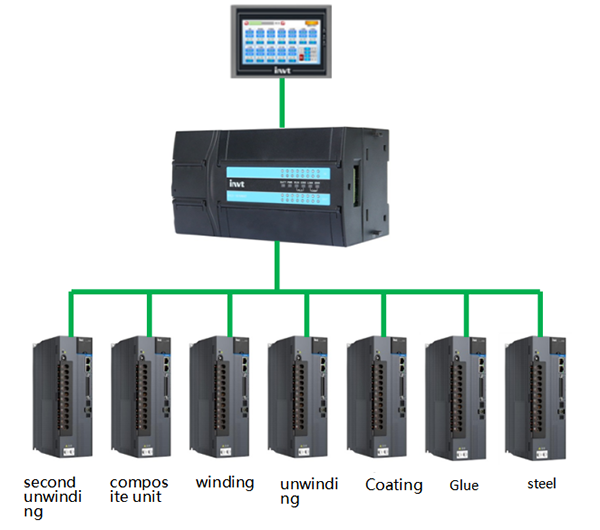

Based on customer needs, INVT recommends the system solution of INVT VS series HMI+IVC3 series PLC+DA200A servo to customers.

The composite servo serves as the host, runs in speed mode, and sends the speed to the first servo and the second servo through the CAN bus, and sends the speed to the winding servo and coating servo through the pulse frequency division output, so that the five The workstations maintain linear speed synchronization. The rubber roller servo and steel roller servo run in the normal speed mode and operate at the set proportional speed of the compound speed.

Program features

Through INVT's solutions, the value generated to customers is as follows:

1. In terms of operating efficiency: the operating speed is 300m/min, meeting customer needs.

2. In terms of operation and maintenance costs: higher cost performance and more competitive.

3. In terms of installation space: DA200A series servo drives have higher power density, and the use of 7.5Kw servo reduces the volume by more than 70%, saving the installation space of the control cabinet.

4. In terms of tension control: DA200A integrates a tension control algorithm internally, and different tension control modes can be selected. At workstations that require tension control, the program adopts closed-loop speed mode, which can achieve smooth start-up and no jitter, acceleration or deceleration at low speeds. The tension is relatively stable during rapid start and stop, ensuring the neatness and taper of the winding and unwinding. The system is simple and efficient, and has a long service life.

Site figure

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.