In recent years, with the continuous development of China's economy and the increasing awareness of oral health, consumers' willingness to consume oral care has also increased. In the context of the rapid rise of Internet e-commerce industries such as "live streaming", dental floss, as an important tool for daily oral cleaning, is being used more and more frequently. As of 2023, the market size of China's dental floss industry will be about 654 million CNY, and it is expected to continue to increase in the future.

1. Customer needs

With the increase of market demand, the requirements for dental floss cartoning machines are getting higher and higher, and the current old equipment has the following problems, which need to be optimized and upgraded:

1 Mold replacement is cumbersome, and product switching takes too long;

2. The cartoning efficiency is low, which cannot meet the terminal production needs;

3. The number of boxes is inaccurate, resulting in waste of resources and affecting user experience.

2. INVT solution

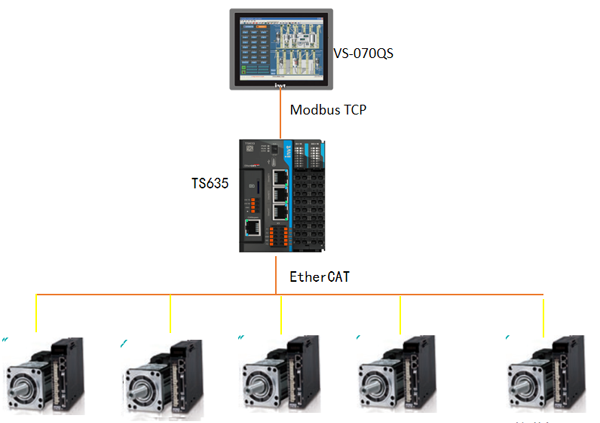

In order to meet customer needs, INVT has launched a new solution: HMI+TS635 series PLC+DA200A series servo drive. The scheme adopts TS635+DA200A bus control technology to ensure the stable and reliable operation of the dental floss cartoning machine.

HMI+TS635+DA200A complete set of INVT solutions, in terms of touch screen interaction, the system has built-in shortcut functions such as one-key return, one-key reset, one-key start, data monitoring, etc., which is convenient for operators to quickly operate and equipment maintenance personnel to quickly identify problems. In addition, the whole equipment is controlled by IMS20B servo motor, which has fast response, accurate positioning, improved production efficiency and improved stability of packaging products.

3. Solution value

Compared with the traditional dental floss cartoning machine, it has the following characteristics:

* Full servo control, flexible action, one-key changeover according to the formula;

EtherCAT bus servo control is used to solve the problem of pulse interference, simplify the integration workload of electrical cabinet, ensure positioning accuracy, and improve response speed.

* Double-station structure, parallel operation, double the production efficiency;

Feeding, dialing, transferring, cartoning, track multi-axis cooperation to complete the automatic cartoning action, double-station operation, to solve the problem of low efficiency; The servo replacement cylinder is used to automatically adjust the position according to the height of the product, which solves the cumbersome mechanical adjustment of the size; The product is switched to 1S to complete the order change, which greatly reduces the time of machine adjustment;

* Use visual positioning to greatly improve the accuracy of cartoning positioning;

The visual positioning scheme is adopted, and the TCP communication efficiency with the controller is high, which solves the problem of inaccurate number of cartons; For a variety of specifications of products, the vision system retrieves matching templates.

4. Conclusion

INVT system solutions have successfully upgraded the dental floss cartoning machine program through its excellent performance and flexible application to realize automatic packaging production, providing users with more efficient and convenient solutions.

In the future, INVT will continue to conduct independent research and development, bring customers all kinds of customized solutions, replace traditional technologies with low consumption, low pollution and high efficiency, promote the sustainable development of the industry, and help customers achieve new breakthroughs.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.