Summary

Take the fan and feed water pump on the boiler of Pakistan's HAMZA sugar factory as an example, compare the advantages and disadvantages of the two adjustment methods of using air damper (valve) and INVT medium voltage variable frequency drive (MV VFD, Hereinafter referred to as MVD), and changing the fan (water pump) speed. The specific application of INVT MVD in sugar factory boiler load equipment demonstrates that the use of GD5000 series MVD to adjust the speed of fans, water pumps and other equipment can achieve low investment, fast effects, and significant energy saving benefits.

Keywords

GD5000, boiler, induced draft fan, pump, medium voltage variable frequency drive, sugar factory, Pakistan

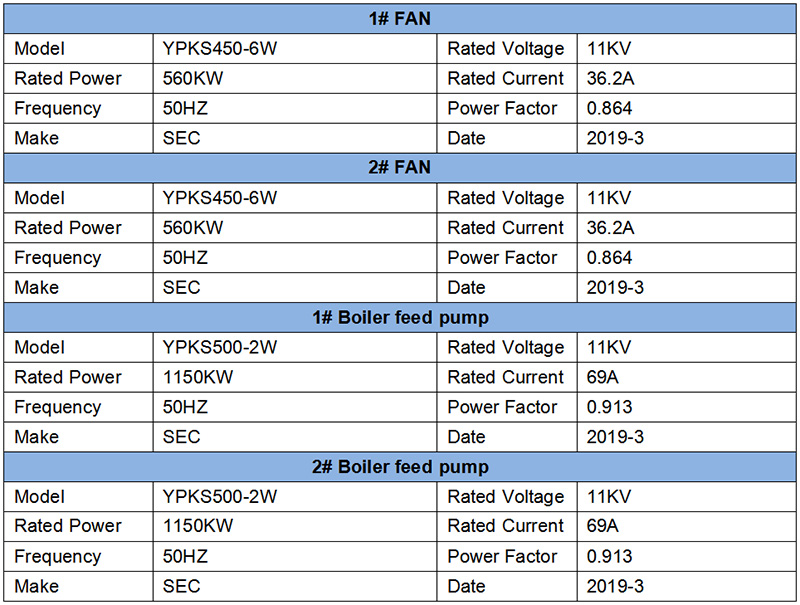

Detailed motor parameters are list as follow

Fan process requirements

The induced draft fan is an important part of the production process of the sugar factory boiler, and the induced draft fan needs to exhaust the flue gas produced by the boiler outdoors. Because the flue gas of the boiler needs to pass through the de-layer and desulfurization system, the resistance is relatively large, and an induced draft fan is required to discharge the flue gas and increase the negative pressure of the combustion chamber in the boiler body.

Boiler feed pump process requirement

The boiler feed water pump is the same as the induced draft fan. It is configured as a double-use plan and consists of two identical water pumps. The purpose is to ensure that the water supply is normal and the pressure of the boiler water supply is normal.

2. System Configuration

2.1 MVD system instruction.

According to the demand on site, the MVD consists of buffer cabinet, transformer cabinet, power unit cabinet and control cabinet. This GD5000 MVD has the functions of local/remote button, emergency stop button on control cabinet.

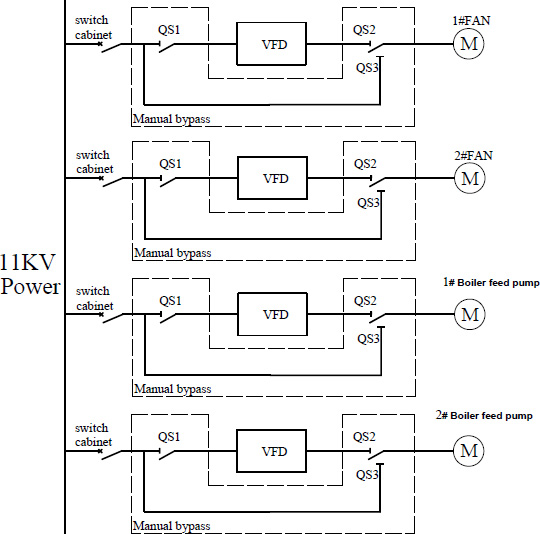

INVT suggest VFD solution

| VFD Model | Power | Rated Voltage | Rated Current | Other |

| GD5000-A0710-11-S*2 | 560kW | 11kV | 37A | / |

| GD5000-A1400-11-S* | 1120kW | 11kV | 73A | |

| GD5000-MS | / | 11kV | 400A |

The project uses four sets of GD5000 series two-quadrant MVDs independently developed and produced by Shenzhen INVT Electric Co., Ltd. to drive and control the fans and pumps. This drive is a medium voltage variable frequency device with vector control two-quadrant H-bridge series multi-level technology dedicated to fan and pump loads.

The system is equipped with a manual bypass cabinet independently produced and developed by INVT. When the MVD needs maintenance or fault, the bypass cabinet can realize power frequency bypass to ensure that the load does not stop.

3. MVD technology introduction

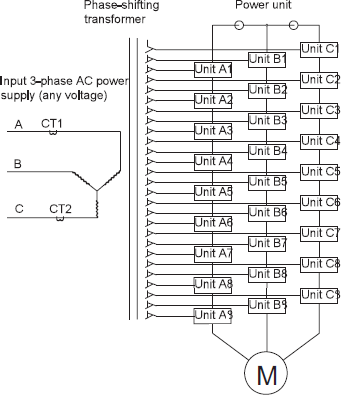

INVT GD5000 series MVD is a high-tech energy-saving product, using advanced IGBT power unit multi-level technology, digital control technology, SPWM pulse width modulation technology. It has the advantages of high power factor, high efficiency, energy saving, and high stability.

Each phase of the whole machine is composed of nine power units connected in series, with three-phase Y connection output. The output adopts the superposition of SPWM waves output by nine power units per phase to form a high-quality output waveform, which is supplied to the motor to drive the load.

Optical fiber communication is adopted between the control cabinet, power unit cabinet, transformer cabinet, and bypass cabinet to prevent electromagnetic interference. Complete isolation of high voltage and low voltage to improve safety.

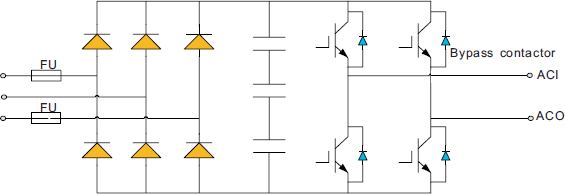

The input side of the power unit is composed of fast melting, rectification and filtering parts, and the rectification part is composed of six diodes, which integrate the DC bus. The inverter part consists of H-bridge inverter output composed of four IGBTs, and the units are connected in series to drive the motor.

4. Application and Advantage

High reliability. INVT GD5000 series inverter has complete protection functions, such as overcurrent, overvoltage, overload, stall and other protection functions.

Reduce the current impact. The maximum starting current when the motor start directly is 7 times the rated current, the motor soft starter should also reach 2.5 times. Observing the inverter actually put into operation by our company, it can be found that there is basically no impact when it starts, and the current starts from zero, but only rises with the increase of speed, and basically does not exceed the rated current. Therefore, the variable frequency operation solves the problem of large current impact when the motor starts, eliminates the impact reaction force of the large starting current on the motor, transmission system and the host, and greatly reduces the daily maintenance costs.

The speed range is wide. The frequency conversion speed control system belongs to the stepless speed control. During the acceleration and deceleration process, the motor control is stable and the speed control is soft.

Extend the life of the equipment. The use of the MVD can make the motor speed change along the fan's acceleration and deceleration characteristic curve, without stress load acting on the bearing, and extending the life of the bearing. At the same time, the relevant data shows that the mechanical life is proportional to the reciprocal of the speed. Reducing the speed of the fan can double the life of the fan, and the use cost of the fan is naturally reduced.

Reduce noise. After using the MVD, the noise is greatly reduced while the fan speed is reduced. When the speed is reduced by 50%, the noise can be reduced by more than ten decibels. At the same time, it eliminates the slippage and sharp contrast during shutdown and startup, and overcomes the defects of poor linearity and poor adjustment quality, which cause pipe hammering and resonance, and cause strong resonance of the pipe. After the fan is running at variable frequency, noise and resonance are both greatly reduced, the change is considerable.

Support power frequency bypass, support power frequency conversion, when the MVD fault or needs maintenance, it can be switched to the power frequency mode to run. Ensure that the load can continue to run.

Increase grid line power factor. Power factor is greater than 0.97,so don’t need reactive power compensation device.

Energy saving. As the project is a new boiler construction, and the client is currently unable to be fully put into operation. Therefore, the actual energy-saving effect will be supplemented based on subsequent customer usage. According to theoretical calculation, the energy saving is expected to be 20%-30%.

5. Conclusion

According to the current project information, the energy saving effect is obvious after using MVD, and the adjustable frequency range meets the requirements of the production process. Considering the safety of equipment operation, adjust the air volume (or water supply) by changing the motor speed to avoid the danger caused by the vibration of the air damper (or valve). Considering the service life of the equipment, due to the reduced speed operation, the vibration, wear and noise of the equipment are reduced, thus prolonging the maintenance cycle and service life of the equipment. Comprehensive considerations, the use of MVD for control of the boiler fans and feed pumps in sugar factories is highly recommended. INVT will continue to stay true to its original intention and strive to create more value for customers in China and around the world.

References

[1] GD5000 Series High-voltage Variable Frequency Speed Control System Manual. Shenzhen INVTt Electric CO., LTD.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.