Climate Reliability Laboratory, covering an area of 300m2, is located in 1F of INVT Guangming Industrial Park, and has been accredited by CNAS Lab. It is in the charge of professional system engineers, and operates in accordance with high quality, high efficiency, and high execution standards. At present, it can realize the simulation test items of general climatic environment, harsh climate environment and complex and variable environment, which provides the basis for the reliability of our products in the environment of design verification, market application and product defect tracking.

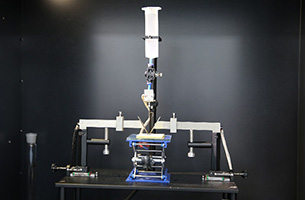

The laboratory has a number of climatic test equipment with various environmental stress tests such as temperature, humidity, air pressure, salt spray, non-standard climate, etc., covering different types and sizes of components, single board, and complete machines to undertake the sample test of each SBU, and the corresponding test process specification is established. The three comprehensive test systems that are rare in the industry can simultaneously perform three environmental stress tests of temperature, humidity and vibration, which can simulate the environmental stress experienced by the product in actual use more realistically and quickly, and expose product defects faster and earlier. There are thermal shock chambers that can achieve a wide temperature range test of -70~150 °C, which can meet the multi-cycle impact test of various products of devices, single board and complete machines. A chamber with a combination of low air pressure and temperature simulates the effects of plateau high altitude on the heat dissipation and sealing of the prototype. The damp heat test chamber with temperature and humidity combination can simulate abnormal problems such as the drop of electrical insulation of the sample machine in high humidity environment. There is an alternating salt spray corrosion box, which can verify the resistance of the connector, the three-plate anti-paint, and the salt spray corrosion resistance of the whole machine components.

In order to further utilize the products in various harsh environments, the company has specially developed non-standard test boxes for cotton fabrics for the textile industry, non-standard test chambers for oil contamination of air compressors, and non-standard test chambers for condensation of outdoor products, which greatly reduces the failure rate of the product under severe conditions, improves product quality and increases the competitiveness of the industry. The non-standard test chambers are designed and developed using the company's existing inverters, PLCs, and HMI products, and are widely used with high reliability.

1. Three comprehensive (temperature / humidity / vibration) test system, rapid temperature change box, thermal shock test chamber

2. Cotton floss non-standard test box, oil contamination non-standard test chamber

3. Condensation non-standard test chamber, alternating salt spray test chamber

Facebook

Facebook

Twitter

Twitter

Google+

Google+

LinkedIn

LinkedIn

Prev

Prev