Mechanical reliability laboratory provides a basis for the reliability of our products in the aspects of design verification, packaging and transportation, and market problem tracking. The laboratory covers an area of 150㎡, whose management system meets the requirements of ISO/IEC 17025 international standards. It is in the charge of professional system engineers, and operates in accordance with high quality, high efficiency, and high execution standards. At present, it can complete all kinds of vibration and impact test, drop test, pile-up test, Shell test, Hammer test, keyboard and touch screen test, etc.

Among them, the 5T large thrust vibration table adopts the settlement installation, and the horizontal sliding table is almost flush with the ground, which greatly reduces the drop between the table and the floor, and is equipped with an electric cantilever crane for handling major test samples and fixtures to ensure handling process is safe, convenient and labor-saving. It is also equipped with a professional sound-proof monitoring room, which can greatly reduce the impact of noise caused by vibration on personnel. The vibrating table can complete the vibration test of different types of samples from the device, the single board to the whole machine, and various types of prototypes, fully satisfying the vibration level and impact level test of the electric vehicle driver and so on. The drop machine and the carton compression tester can perform a full set of verification on the package materials to simulate the normal pressure and accidental drop of the package material during actual storage and transportation. The shell impact tester and the pendulum tester can check the strength of the chassis to ensure that the sample can withstand the impact and compression within a controllable range in actual use. The programmable button life tester can perform a predetermined number of key tests on the keyboard and the touch screen, so that the key reliability reaches the standard required level.

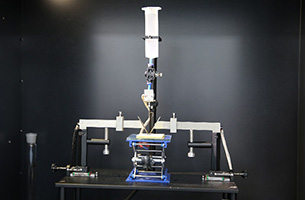

Electric vibration test system

There are industry-leading 5T large thrust vibration system which can perform various types of vibration tests such as frequency sweeping, random, shock, etc., and is equipped with a full set of extension tables and various types of vibration fixtures.

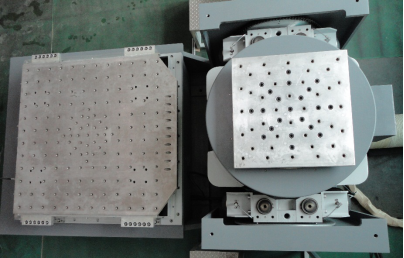

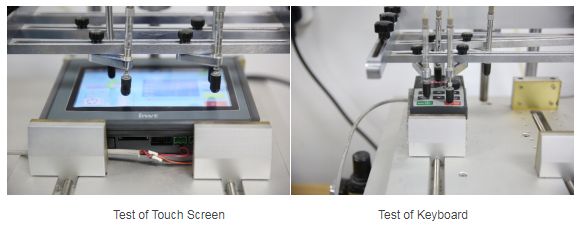

Programmable keyboard life test machine

Compatible with touch screen and keyboard test, it can be conducted more than one continuous test at the same time and each keypad can be customized according to the program flexible control.

Drop machine and carton compression testing machine

The drop machine can carry out the drop test of different angles of the corners, edges and faces of the package. It can also carry out the drop test of the whole machine. It can be combined with the data acquisition instrument to collect the force value data of the drop process to verify whether the package design meets the design value.

The carton compression tester can simulate the pressure damage caused by the stacking of the package material during the actual storage and transportation process, and verify whether the package material design is reasonable.

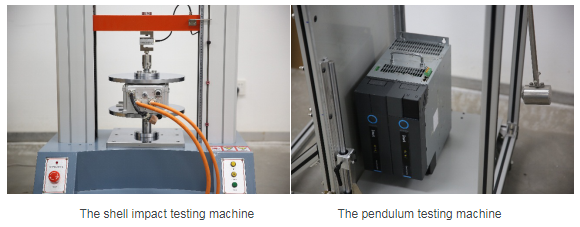

Shell impact testing machine and pendulum testing machine

The shell impact testing machine is used to simulate the shell damage caused by the abnormal pressure in the use of sheet metal chassis, and to reduce the IP grade. And the pendulum testing machine is used to simulate whether the abnormal impact of the sample case can still guarantee the functional safety and normal performance of the sample.

Facebook

Facebook

Twitter

Twitter

Google+

Google+

LinkedIn

LinkedIn

Prev

Prev