Packaging transportation is generally divided into motor transportation, rail transportation, air transportation, and ship transportation. Different transportation will cause different vibration environments. The vibration is normally random. Its intensity is as follows: air > motor > rail > ship. In the laboratory, the packaging vibration test is usually performed with a transportation simulation test table or an electromagnetic vibrator. The standard transport road spectrum or the actual collected transport road spectrum is written into the controller as input condition for test. The packaging vibration test is used as a part of a series of tests for package (such as temperature and humidity storage, vibration, stacking, etc.).

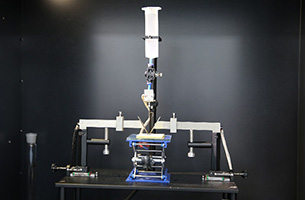

Test method: After selecting the cargo transportation mode, determine the test magnitude and the test time. By starting the test, place the transportation package on the vertical surface of the vibration test equipment in the actual transport direction and usually in an unfixed manner. Surround the sample with a frame to ensure that the transportation package can perform a certain distance of unconstrained movement in each horizontal direction without falling from the table. A load container can be added on the top of the package to apply a weight. Binding the package and the weight together for vibrating can realistically simulate the top stacking pressure that the product will experience during actual transportation.

Test standards: GB/T 2423.56, GB/T 4857.23, GB/T 35774, IEC 60068-2-64, ISTA series are commonly used.

Test conditions: The figure below is the test spectrum of commonly used standards. The frequency range is generally lower than 500Hz, PSD is between 0.000004—0.06g2/Hz, and the test time is 30—180min/direction.

Test equipment: We use electromagnetic vibration test tables for packaging vibration test. Currently we have 1T and 5T propulsive-force vibration machines, which can adapt to the package vibration test of a full range of products.

Product improvement:

1. Casing abrasion reduced: Usually there is a matching gap between the cushioning material and the prototype. If the cushioning material is too soft and the matching gap is too large, it may cause abrasion marks on the product shell. Tests can be conducted to check whether the packaging material and the design tolerance are appropriate and whether the anti-abrasion PE bag is effective.

The following figure shows the abrasion marks on the surface of product shell.

2. Internal large device support verification: The transportation conditions of the package are usually harsher than the vibration environment in which the product is actually used. If the fixation strength is insufficient or there is no auxiliary limit support, the large and heavy components such as transformers, reactors, etc., are easy to break the sheet metal of the fixing place during transportation.

Facebook

Facebook

Twitter

Twitter

Google+

Google+

LinkedIn

LinkedIn

Prev

Prev