The raw materials of the textile industry are natural fibers (cotton, wool, silk, hemp), man-made fibers (artificial silk, artificial cotton, artificial wool, etc.), and synthetic fibers (acrylic fibers, polyester, nylon, etc.). Different raw materials differ in particle size and length of dust. The length of slender textile fiber is 2.5 cm to 6.5 cm, and the length of fine staple cotton planted massively in our country is generally from 25mm to 35mm. If the fine dust produced in the production of the textile industry is mixed with large dust and short wool, it is difficult to separate them, and may cause air duct blockage of mechanical equipment and accumulation of cotton batting inside the shell, which will affect the normal operation of mechanical equipment over time.

Through the cotton batting test, we can simulate a poor working environment where industrial products often encounter dust and cotton batting in the textile processing industry to verify the influence from suspended dust, cotton batting, and other solid suspensions in the air imposed on the air duct structure and electrical performance of the products. It is suitable for all industrial control products produced by our company.

Test conditions:

Cotton for testing: Short-staple cotton is generally used in the test. You shall ensure that the cotton for testing is dry and fluffy, and there shall not be a large number of knotting, balling, caking and other phenomena. Note that cotton for testing shall be replaced regularly.

Circulating air: To make the cotton float, it is necessary to connect to the constant airflow to maintain the cotton batting concentration in the air.

Testing time: Select the testing time according to product volume, enclosure type and degree of protection, such as 2h, 4h, and 8h.

Test category:

It can be divided into cotton batting test for non-forced air-cooled specimens and cotton batting test for forced air-cooled specimens.

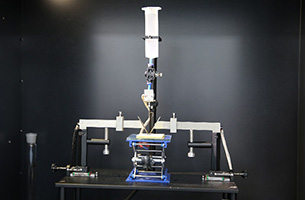

Test equipment:

We have developed cotton batting test chambers for VFDs special for the textile industry, and the HMIs, PLCs, and other important components used by the test chambers are developed by our company. The design, installation and debugging of the hardware, and the design and debugging of the operation interfaces and background programs are completed independently by our R & D personnel.

The test chambers are mainly used to verify the VFDs that easily suffer from air duct blockage caused by cotton batting in the textile industry.

Product improvement:

1. Temperature rise is too high: Because the heat dissipation mode of some products is air-cooled, conventional cooling fin spacing may cause cotton blocking, resulting in the reduction of supply air rate, and high temperature rise due to poor heat dissipation of the product.

You can observe the area where cotton batting often block through the test, increase the spacing among cooling fins and redesign the air duct so as to prolong the service life of the product.

2. Cotton batting accumulation inside the product: Strong electrical devices such as modules and transformers are easy to absorb cotton fibers. When the product becomes damp, the cotton fiber lapped at the device pin will be turned into a conductor, which may cause the product short-circuit and blasting.

Through the test, we can find out the channel entry of cotton batting to optimize the channel blockage. In addition, we can strengthen the protective coatings such as conformal coating on the parts that are easy to absorb cotton batting so as to reduce the failure rate.

Facebook

Facebook

Twitter

Twitter

Google+

Google+

LinkedIn

LinkedIn

Prev

Prev