Condensation refers to a phenomenon that when water vapor reaches saturation in the air, it condenses on objects with relatively low temperatures.

The condensation test simulates the destructive effect of outdoor condensate on the product by acting directly on the test specimen. Within a period of time, the damage caused by months or years of outdoor moisture can be reproduced. Use 100% condensation humidity to simulate and accelerate damage to metals, paints and organic materials caused by rain water and dew. The natural exposure process is accelerated by increasing the humidity temperature, which is an effective supplement to the ordinary (non-condensing) humidity test, so as to make the product more adaptable to the extreme climate environment.

Test standards: ISO 6270-2, ISO 16750-4, and ASTM D4585 are commonly used.

Test conditions:

ISO 6270-2 test conditions:

Internal test conditions:

1) Severity level I is used to simulate that the working environment of the product is a place with certain climate protection, and short-time condensation may occur.

2) Severity level II is used to simulate that the working environment of the product is a place without temperature and humidity control, and phenomena such as short-time condensation and sample upper part dripping may occur.

3) Severity level III is used to simulate that the working environment of the product is outdoor, and long-time condensation caused by large temperature difference between day and night may occur.

Test category: It can be divided into severity level I, severity level II, severity level III, etc.

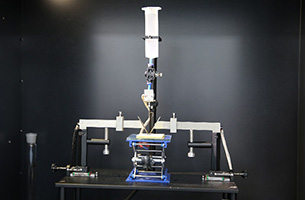

Test equipment:

Our company is equipped with test chambers special for condensation test, and the HMI, PLC, and other important components used by the test chambers are developed by our company. We have successfully applied for design patent and utility model patent of these components.

The test chambers are mainly used to verify the situation that condensation occurs easily during the operation of the variable frequency drive (VFD) and solar inverter.

Product improvement:

1. Detect unreasonable safety spacing: The charged part of the specimen may cause leakage, short circuit and electrochemical reaction due to moisture, resulting in explicit or implicit circuit faults, such as the decrease of machine insulation resistance, or module direct short circuit blasting.

Such problems can be found and corrected timely. The safety spacing of single component may be sufficient, but after splicing and assembly, the safety spacing may be too close. The missing problems can be found and rectified through conducting the condensation test.

2. Anti-condensation performance of conformal coating devices is not covered: The PCB board suffers from heat and damp, expansion, deformation and short circuit, electric leakage caused by stagnant water. For example, the circuit board inside the fan is short-circuited due to stagnant water, triggering the front-stage switching power supply short-circuit protection, resulting in the loss of other circuit functions that share this switching power supply.

We can find weak devices and make targeted improvements to improve the process, replace with high protection devices, change the structure, or design hardware protection.

Facebook

Facebook

Twitter

Twitter

Google+

Google+

LinkedIn

LinkedIn

Prev

Prev