The equipment development laboratory covers an area of 300m2, whose business focus is to provide the automatic test system, comprehensive measurement & automatic test solutions for for each SBU. It is mainly used in industrial automation, new energy vehicles, network power, rail transit, intelligent manufacturing system, and intelligent factory. The laboratory has 18 employees, 62% of which have bachelor degree or above. Besides, it owns 12 patents.

1. Equipment business technical section chart:

It conducts certification, test, and failure analysis on the auxiliary materials used by the group through using professional test equipment and technology.

2. Development history of the equipment development

1. First generation: Manual test.

Advantage: Low cost.

Disadvantage: Low efficiency and uncontrollable quality.

2. Second generation: Semi-automatic test.

Advantages: Value for money, high efficiency, and basically controllable quality.

Disadvantages: Manual handling is required.

3. Third generation: Full-automatic test.

Advantages: Parallel test, high efficiency, quality assurance, high product consistency, remote monitoring, and unmanned operation.

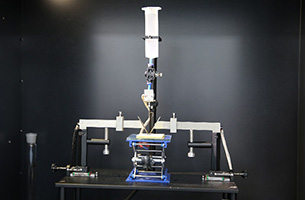

3. Main equipment:

The laboratory has developed a number of test systems, the main equipment are shown as follows.

Rail Transit Aging Feedback Platform

Facebook

Facebook

Twitter

Twitter

Google+

Google+

LinkedIn

LinkedIn

Prev

Prev