The process automation laboratory, covering an area of about 160m2, is mainly responsible for basic process research, process failure analysis and verification, and research and promotion of intelligent manufacturing of INVT group.

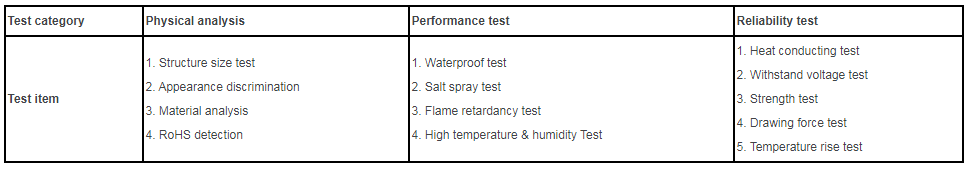

1. Auxiliary material certification and process research involving in the basic process research:

Auxiliary material certification: Conduct the certification, test, and failure analysis on the auxiliary materials used by the group through using the professional test equipment and technology.

Process research: Study the production process, and improve the process technology, process plan and process route. Follow up new process technology and development trend of product design and production in the industry, and reserve new technology and timely introduce it into the existing process system. Introduce new materials, develop new tools and equipment, improve production efficiency, and ensure the consistency of product quality. Formulate the manufacturability standard, and drive the product development and design.

2. Process failure analysis and verification

Analyze the process failures in the production processes or fed back by the market, propose the improvement measures, and conduct the process verification on assembly of key components and key production processes.

3. Research and promotion of intelligent manufacturing

It studies the relationships between people and people, people and intelligent devices, and intelligent devices and intelligent devices, forming a complete intelligent manufacturing system.

Classification map of auxiliary materials

All-in-one product automation production line scheme

Key process intelligent workstation

Facebook

Facebook

Twitter

Twitter

Google+

Google+

LinkedIn

LinkedIn

Prev

Prev