Covering an area of 80m2, the Pilot Run Laboratory builds the thorough pilot run verification and process development platforms dedicating to the research and related technical reservation of new process, new material, new technology, and new standard. The businesses it undertakes: prototype structure process assembly verification, prototype trial production, development and verification of manufacturing process, and development and verification of process and tooling. At the same time, it provides production resources and technical support for trial running of the prototype. The Pilot Run Laboratory has planned the remote joint verification system and established the remote visual cooperation mechanism between Shenzhen INVT Pilot Run Lab and Suzhou INVT Pilot Run Lab, which can realize the functions of remote online verification live broadcast, remote verification exception handling, and remote online production guidance.

There are a number of experienced technicians in the Pilot Run Laboratory, including PCBA process engineer, assembly machine process engineer, and product trial engineer, providing the best verification scheme and process manufacturing scheme for product design.

Main equipment:

Aging loading equipment: The equipment can be used to conduct the sample on-load aging test and test the reliability of the electrical properties of the product. The equipment feeds the load energy back to the grid through the UPS system for recycling.

Speed and torque tracking test platform: The platform can conduct the speed and torque performance test of 2.2kW and 4kW VFDs and other routine electric performance tests (Tests on 5.5kW and 7.5kW VFDs can be achieved through expanding the platform.)

1. Speed test items include steady speed precision, velocity fluctuation, speed regulation ratio, maximum dynamic speed change, etc.

2. Torque test items include torque boost, start torque, torque control precision, and torque ripple.

3. Other routine test items include overvoltage, overcurrent, overload, and full-load long running, etc.

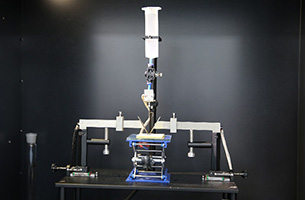

Air tightness test platform: The platform can output air pressure of -100kpa–5000kPa, and conduct air leakage detection on the assess equipment with the leakage detection accuracy up to 1Pa/s. The platform can conduct the IP67 cavity leakage test and water-cooling radiator waterway tightness test.

Facebook

Facebook

Twitter

Twitter

Google+

Google+

LinkedIn

LinkedIn

Prev

Prev