1. Project Background

The direct starting method for high-power AC asynchronous motors inevitably leads to significant current surges, which can adversely affect the power grid and reduce the lifespan of the motor. This surge may also pose risks of operational interruptions for other loads. Commonly, high-power loads can be initiated through solid-state soft starter or series water resistors. Currently, the optimal solution entails using a VFD, which facilitates multi-load configurations and seamless switching between VFD to AC power or AC power to VFD, thus preventing shocks to both the motor and the power grid while reducing maintenance costs and offering numerous additional benefits.

2. Client Requirements

A client in the coal chemical sector in Hami, Xinjiang, has three surplus gas compressors that previously employed solid-state soft starting methods. This approach results in a starting current that typically escalates to 3-5 times the rated current of the motor, thereby causing severe voltage drops in the power grid and increasing the risk of shutdowns for other loads.

The client seeks to retrofit the system with a VFD, allowing for the selection and initiation of any load based on production requirements, coupled with the capacity to switch seamlessly from VFD to AC power without disturbances. Furthermore, the VFD should enable sustained operation within the 5-50 Hz frequency range while retaining the existing solid-state soft start option as a backup. The ultimate objectives are to optimize energy efficiency, ensure smooth startups without voltage drops, and meet process demands.

3. INVT Solution

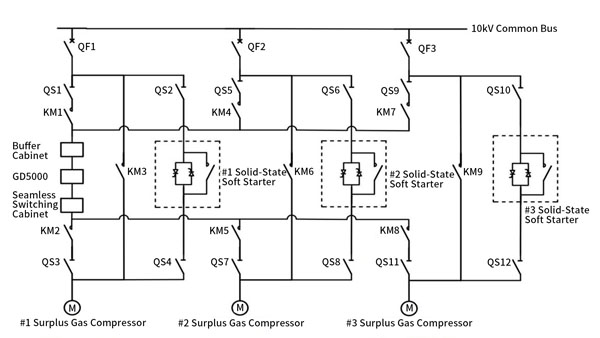

In response to the client's specific needs, INVT has developed a tailored solution featuring the GD5000 Medium Voltage VFD for seamless One-to-Three switching. A schematic of the primary circuit for the conversion plan is shown below:

Selected VFD Model and Motor Parameters:

No. | VFD Model | Motor Parameters |

1 | GD5000-A5600-10-D | 4000KW/10KV/274.5A/1490RPM |

Advantages of this Solution:

3.1 The GD5000 control system employs a multi-core DSP+FPGA+ARM architecture, ensuring high control precision, rapid dynamic response, and substantial low-frequency output torque.

3.2 The solution is custom-designed to fulfill the requirements for uninterrupted switching between loads, allowing for prolonged operation of one load within the 5-50 Hz range while still preserving the existing three solid-state soft start backups.

3.3 The switching cabinets for the three compressors feature mechanical interlocks for the isolating switches of both the VFD and solid-state soft start inputs, ensuring simplicity in operation and enhanced safety.

3.4 The "lock frequency lock phase" control technology facilitates smooth transitions of the motor between VFD and AC power operations without shocks, making it suitable for multi-load configurations or soft starts for high-capacity motors.

4. Client Benefits

4.1 Cost-effectiveness: The INVT GD5000 seamless One-to-Three switching system simplifies operations compared to the previous solid-state starting method. A single converter can start any motor as needed, facilitating multiple consecutive startups with minimal operational impact on the motor, machinery, or power grid.

4.2 Cost Reduction and Efficiency Enhancement: The implementation of VFD system has genuinely enabled soft starting for motors and loads, thus diminishing shocks and effectively prolonging their operational lifespan.

4.3 Safety and Reliability: Compared to earlier starting methods, which caused significant voltage drops that might halt production equipment or necessitate preemptive coordination for restarting heavy loads, the VFD limits starting currents to approximately 0.5 times the motor current, eliminating adverse effects on the power grid and other loads.

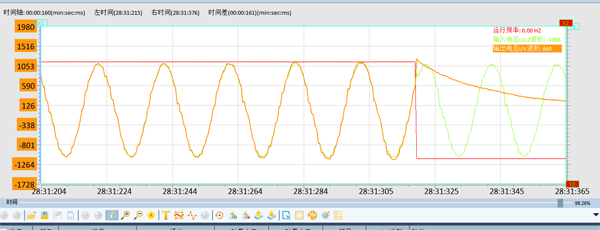

Waveforms during load switching for input and output voltage

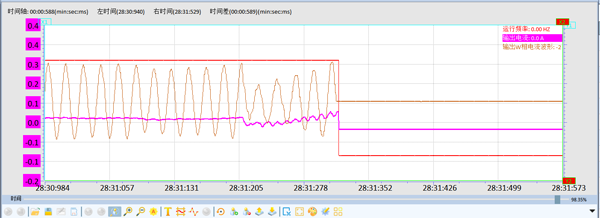

Waveforms during load switching for output current

INVT GD5000 Medium Voltage VFD

GD5000 Three-way Automatic Switching Cabinet

5. Conclusion

Considering the current challenges associated with the initiation of high-power loads, the seamless switching technology associated with VFDs displays clear advantages over traditional starting methods. This solution has commenced broad application across industries with significant high-power load requirements, particularly in compressors and pumps. The successful deployment of the INVT GD5000 three-way solution for high-power compressors in a coal chemical project in Xinjiang has wholly met the client's process demands, optimizing energy efficiency and reducing costs. Since its commissioning, the system has functioned effectively, executing numerous successful transitions with stability and reliability.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.