Abstract: GD380L is special elevator drive developed for all type of elevator like home lifts, passenger and goods lifts etc. This paper gives the detailed solution installation and commissioning details for GD380L. Engineering practices, market survey and feedback shows that GD380L has good control performance and stability.

Keywords: INVT GD380L, Geared Machine.

I.Introduction

GOODRIVE380L series inverters are the new-generation elevator inverters developed on the new INVT control platform. Goodrive380L series inverter improved great achievements in security and reliability, control performance and use functions Basic performance.

Basic performance:

1.Ability to drive asynchronous (Geared )and synchronous (Gearless) motors

2.Support open loop control mode without encoder and closed loop control mode with encoder.

3.Static & rotational motor tuning for the initial pole angle of PM motor

4.Support multiple type of encoder: incremental, sine-cosine, absolute encoders and built in incremental PG card

5.ACC/DEC S-Curve Algorithm: Improve comfort during ACC, DEC and stop.

6.Starting weight compensation with and without weight sensor to prevent reverse slip at startup, ensuring stable lift startup.

7.Emergency-rescue mode & search the direction in light load.

Special functions

8.In-Built LCD keypad interface.

9.In-Built Incremental PG card.

II.Configuration of GD380L elevator

Installation of GD380L on lift has below detail:

Tab 1 Lift information

Lift speed | 1.0 m/s |

Capacity | 6 persons, 408KG |

Floor | 5 floors |

Power supply | 3phase 415V |

Motor type | Asynchronous motor |

Rated power of motor | 3.7 kW |

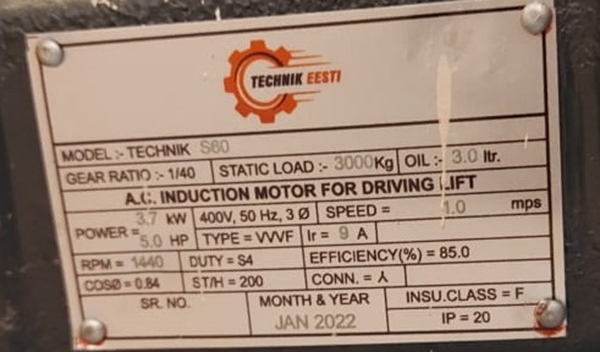

Fig INVT GD380L Control Panel and motor with nameplate

1.GD380L electrical configuration

According to the lift configuration and the demanding functions, we provide the electrical solution as follow. Considering higher ambient temperature, one grade higher of machine rating is selected.

Tab 2 Configuration list

Item | Model | Qty |

GD380L Inverter | GD380L-5R5G-4 | 1 |

Geared Motor | TECHNIK S60 | 1 |

Brake resistor | 65Ω/1500W | 1 |

Fig GD380L Inverter

2.GD380L parameter setting

Basic parameters setting are as follow.

Function Code | Name | Description | Setting Value |

P00.00 | Speed control mode | Sensorless vector control mode 1 | 1 |

P00.01 | Channel of running commands | 1: Terminal | 1 |

P00.02 | Rated speed of elevator | 0.100~4.000m/s | 1.000 |

P00.03 | Speed command selection | 3: Multi-step speed running | 3 |

P02.00 | Motor type selection | 0: Asynchronous motor | 0 |

P02.01 | Rated power of the motor | 0.1~3000.0kW | 3.7 |

P02.02 | Rated frequency of the motor | 0.01~P00.04 | 50 |

P02.03 | Rated speed of the motor | 1~36000rpm | 1440 |

P02.04 | Rated voltage of the motor | 0~1200V | 400 |

P02.05 | Rated current of the motor | 0.8~6000.0A | 9.0 |

P03.00 | Proportional gain of speed loop | 0~100.0 | 25 |

P03.03 | Proportional gain of speed loop | 0~100.0 | 25 |

P05.01 | S1 terminal function selection | 1: Upward running(FWD) | 1 |

P05.02 | S2 terminal function selection | 2: Downward running(REV) | 2 |

P05.03 | S3 terminal function selection | 8: Multi-step speed 1(MS1) | 8 |

P05.04 | S4 terminal function selection | 9: Multi-step speed 2(MS2) | 9 |

P05.07 | S7 terminal function selection | 4: Emergency running(EMER) | 4 |

P06.03 | Relay RO1 output selection | 7: Brake control | 7 |

P06.04 | Relay RO2 output selection | 8: Contactor control | 8 |

P09:00 | Multi-speed 0 | 0.000~P00.02 | 0.200 |

P09:01 | Multi-speed 1 | 0.000~P00.02 | 0.700 |

P09:02 | Multi-speed 2 | 0.000~P00.02 | 0.075 |

III.Conclusion

After installation of GD380L, the elevator runs perfectly. The customer is very satisfied. And GD380L can support to open loop, closed loop for Geared & Gearless machine, have LCD display for convenient debugging.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.