1.Introduction

Mine winch hoist is the main tool used to send the track train to the designated position for underground and external transmission.

Original drive system has below disadvantage:

1. Poor smoothness of speed regulation.

2. Low control accuracy and small speed adjustment range.

3. Not only the energy loss is high, but also the input voltage fluctuation has a great influence on the speed.

4. Low stability.

Project load photo:

2.INVT solution and system diagram

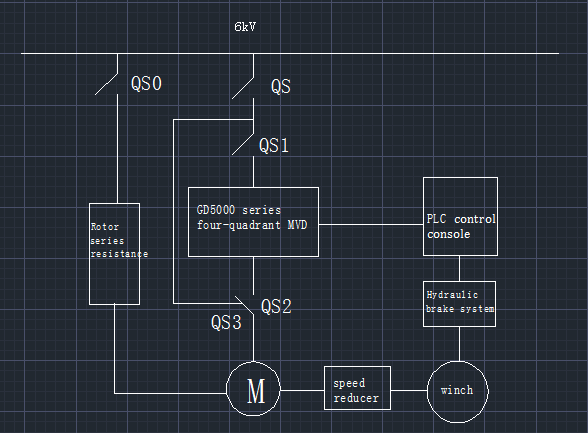

INVT GD5000 series four-quadrant MVD transform the old control and drive system, keep the original brake system and PLC control console with the new mv drive.

The system is equipped with manual bypass cabinet independently produced and developed by INVT.

VFD system diagram:

3.Features and advantages

High reliability, The GD5000 series inverters of INVT have perfect protection functions, such as overcurrent, overvoltage, overload, stall and other protection functions.

Small starting current, the impact current in the process of starting and accelerating is small, and the maximum starting current in the process of accelerating does not exceed 1.9 times of the rated current.

Wide range of speed regulation, VFD system belongs to the stepless speed regulation, the motor control in the process of acceleration and deceleration is stable, the speed regulation is soft.

Energy saving space is large. As a kind of lifting VFD, the fundamental problem of INVT GD5000 series four-quadrant VFD is to deal with the feedback energy.

Production efficiency is high, the VFD can control the motor to run stably at a given speed, speed, position, lifting signal, the main order and other peripheral links, can achieve automatic control.

Support power frequency and frequency conversion switching function, support power frequency conversion switching, when the VFD failure or need to maintain, can be switched to the mode of power frequency operation. Power frequency can use the old system to drive the operation, do not delay production.

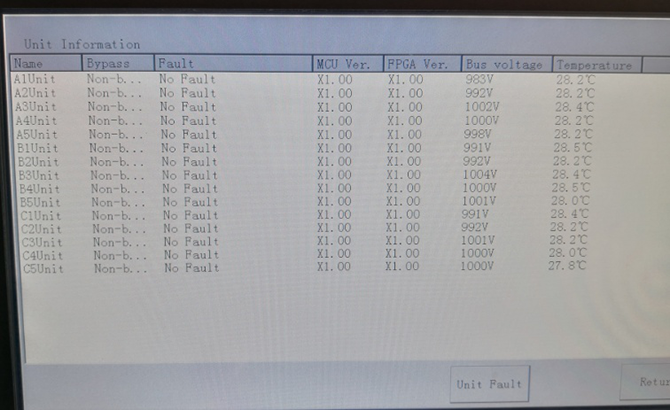

Photos of the converter in operation:

4. Summary

The practice has proved that the elevator in coal mine runs well after the technical transformation of VFD, the energy consumption of the elevator is reduced, the lifting capacity of the elevator is increased, and the power factor of the power grid is also improved. It can completely replace the traditional control mode and has very high promotion value.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.