Summary: In this paper,through introducing INVT GD5000 medium voltage inverter applied to Jet condenser for Vacuum Pan in the sugar factory in the Thailand, to illustrate VFD transformation of the feasibility and the significant energy saving.

Keyword: GD5000 medium voltage inverter, jet condenser, energy saving.

1.Introduction

The process of sugar crystallization is very important part in the whole sugar production. Normally the sugar factory use vacuum pan to heat sugar water. After the concentration of sugar water get to limited values, the sugar water go to next step. So if the vacuum pan is running, the sugar factory need use jet condenser to cooling the vacuum pan.

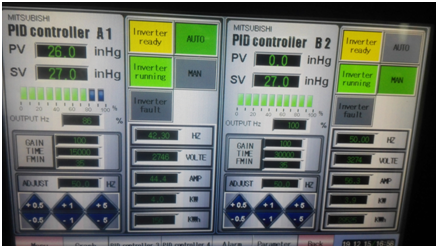

Below figure is about logic control and display system for Vacuum pan.

Figure 1.The control and display of Vacuum pan

Normally in the sugar factory, they use pumps for jet condenser.

But almost all of the pumps were directly driven by grid power.

There are some disadvantages for grid power directly driving pumps:

1)The speed of running pump can’t change. Actually pumps

do not always running at rated speed.

2)The pressure of water is not stable.

3)When directly start pumps, there is large impact current and impact voltage for grid power and pumps, they are no good for grid power and pumps.

Finally the customer want use inverter to drive pumps.

2.Project Analysis

SURIN sugar plant is a big sugar factory in Thailand. The average of sugarcane milling capacity is about 3,000 tons/day. There are many pumps for vacuum pan cooling.

Detailed parameters are list as follow:

Table 1 Prepressing Motor Parameters

| Motor Model | Power | Rated Voltage | Rated Current | Rated Speed | Power Factor | Load Type | Quantity |

| Y2-400-4 | 315KW | 3.3KV | 68A | 1490RPM | 0.85 | Pump | 2pcs |

On-site pictures:

Figure 2 Pump and it is nameplate

Figure 3 Load and Devices on site

3.System Configuration

According to the demand on site, there are local/remote button, emergency stop button and power frequency/variable frequency indicators on the panel of control cabinet, and also /input power/ output power/power factor parameters display on in the HMI. The variable frequency driver is the GD5000 series high-voltage inverter, produced by Shenzhen INVT Electric CO., LTD.

Below figure is about inverter system diagram:

Figure 4 System diagram of the inverterFigure 4, System diagram of the inverter

On-site pictures:

Figure 5 application on site

4.Application and Advantage

After using inverter, there are some advantages as follow,

1)Be able to soft start, start time and start method can be adjusted based on the situation on site.

2)Higher power factor. Over 0.95, prevent from using power factor compensation device and be fined.

3)Without harmonic pollution to the motor and efficiently drop the heat of the motor.

4)More protection for pumps; Such as overcurrent / overvoltage / overheat and so on.

5)Increase lifetime of pumps;

6)Reduce the loss of shutdown maintenance and save plenty of maintenance costs.

7) Significant energy saving:

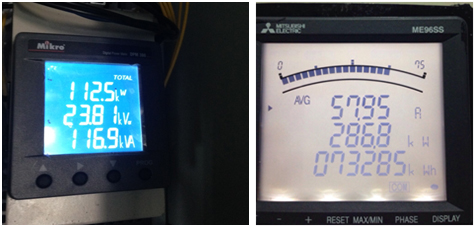

Below table is after using inverter energy saving:

Use the inverter and No use the inverter

Energy saving ratio: (286.8-112.5)/286.8=60%.

5. Conclusion

After using medium voltage drives, there are many advantages, especially significant high energy saving ratio. The customer can get their investment back quickly. The upgraded inverter system works well, customers are satisfied.

References

[1] GD5000 Series High-voltage Variable Frequency Speed Control System Manual. Shenzhen Invt Electric CO., LTD.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.