Everyone loves to eat sweets. So, where does sugar come from, and how many processes does it go through to form?

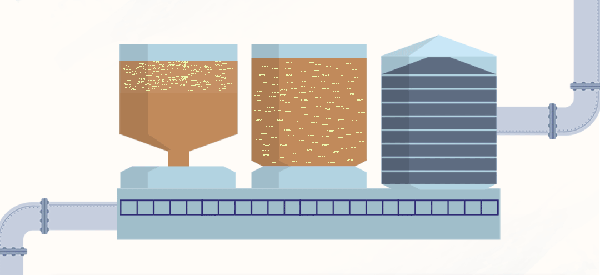

1. Sugarcane pretreatment

Sugar cane uses crushing equipment such as a sugar cane cutter and tearing machine to cut and tear the sugar cane into filamentous cane.

The equipment in the pretreatment stage includes: belt conveyor, bridge crane, tearing machine. INVT GD200A, GD350A, GD350-19, GD5000 and other products can be used in these devices.

Benefits brought by VFD drive:

* It can start and stop frequently, has large starting torque and fast torque response;

* Centralized automatic control, which can adjust the operating speed according to output;

* Save electricity. Taking the VFD running at 30Hz as an example, the power saving rate of the belt conveyor and tearing machine is >40%;

2. Crush of sugar cane

The pretreated sugarcane material is pressed with a press to squeeze out the sugarcane juice.

The main equipment in the pressing stage includes: feeder, press, sugar-water mixing pump, bagasse filter, bagasse elevator, bagasse conveyor belt, etc. INVT GD200A, GD350A, and GD5000 series ac drives be used for these devices.

Benefits brought by VFD drive:

* Power saving: The power saving rate of the press is >15%;

* Increased juice extraction rate: The entire line uses VFD and asynchronous motors, and the sugarcane extraction rate is increased by >0.2%;

* Automatic control, which can adjust the system speed according to output requirements;

* System maintenance costs are low.

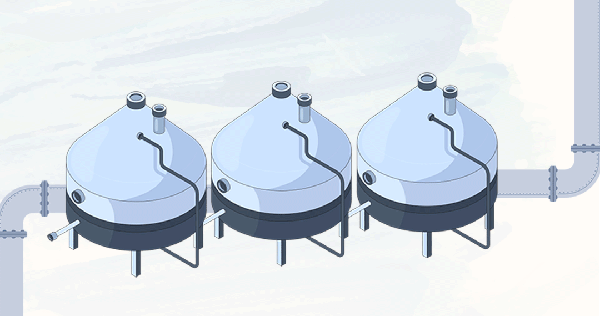

3. Clarification of sugarcane juice

The main clarification treatments include: heating cane juice - adding clarifier - separation and precipitation.

The main equipment in the cane juice clarification stage is various sugar juice pumps; General-purpose VFD such as INVT GD200A and GD350A can drive these pumps and effectively achieve energy saving, automatic control, and PID adjustment.

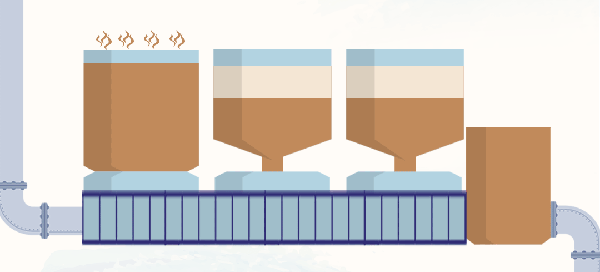

4. Evaporation and crystallization of cane juice

After the cane juice is purified, a clear juice with a concentration of 12 degrees BX (sugar hammer) to 14 degrees BX is obtained. The clear juice needs to be evaporated to remove a large amount of water and concentrated into a syrup of about 60 degrees BX before it can be crystallized. The evaporated sugar juice is concentrated into a paste. The massecuite is unloaded from the sugar boiling tank into the crystallizer. After a gradual cooling process, the crystals are helped to continue to grow and the sucrose is precipitated more completely. This is called crystallization.

The main equipment in the evaporation and crystallization stage of sugarcane juice is syrup pump, jet condensation pump, etc. INVT GD200A, GD350A, GD5000 and other VFD can drive these pumps and help the equipment achieve a power saving rate of more than 40%.

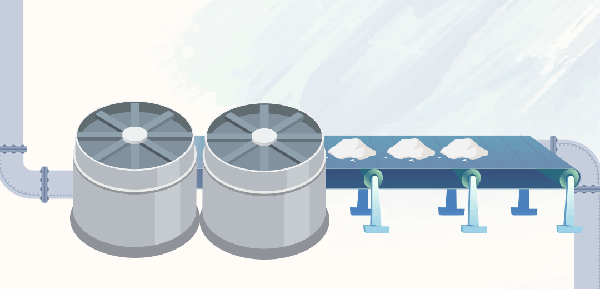

5. Divide honey

Honey separation relies on the centrifugal force generated by the rapid rotation of the centrifuge to throw the molasses out, while the sucrose crystals remain in the sieve basket due to the obstruction of the sieve.

The main equipment in the honey separation stage includes continuous centrifuges, scrapers, and conveyor belts. INVT GD350A and GD800 series VFDs can be used for these devices.

Benefits brought by ac drive:

* Meet process requirements: rapid acceleration and deceleration, fast torque response;

* Energy saving: Both continuous and intermittent centrifuges have a lot of room for energy saving;

* Automation control: rich field buses to meet on-site control methods;

* Excellent overload capacity and stable performance, low system maintenance costs.

6. Drying and baling

Under normal circumstances, the white sugar unloaded from the centrifuge still contains 0.5%-1.5% moisture, so it needs to be fully dried and cooled.

Finally, the sugar is sieved, weighed, and packaged, and it becomes the sugar we buy in the market.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.