Abstract:

This paper mainly presents INVT IVC1S series PLC and DA200 servo drive with ECAM functions used to cutting of the corrugated box as per different sizes. In this project HMI use for data feeding and monitoring of the process.

Keywords: IVC1S PLC, HMI, DA200 servo drive, corrugated box, RS485 communication.

1. Introduction

The major section of this Feeder, Encoder, Cutter Servo, HMI, PLC, AC drive etc.

* Feeder: This application feeder uses a roller and rotate through induction motor and that motor run with AC drives as per speed command from upper computer.

* Encoder: Here 2500ppr to 5000ppr encoder type we can use as pe requirements, encoder used to provide feeding length to upper computer through hardware high speed configuration as well as captures in servo ECAM functions settings.

* Cutter: Here servo installed for cut the length as per setting in upper computers. This servo axis rotates as per feeding speed and ECAM parameters settings.

* PLC and HMI: In automation industry HMI most of the time use for data feeding and operation monitoring. Here 7inch HMI used to for data monitoring and servo modbus communication as well as recipe settings.

* Process: In this application roll feeding from input section with mechanical free roller and that roll feed to feed roller. Here feed roller rotates with induction motor and drive mechanism. Encoder is mounted on feeding shaft and length feedback sent to upper computers in counts format. Finally, cutter axis rotates as per the feeding length and speed synchronizations.

Figure - Fabricated box cutting machine

2. Project information and Solution

Figure – Machine front view and trial setup

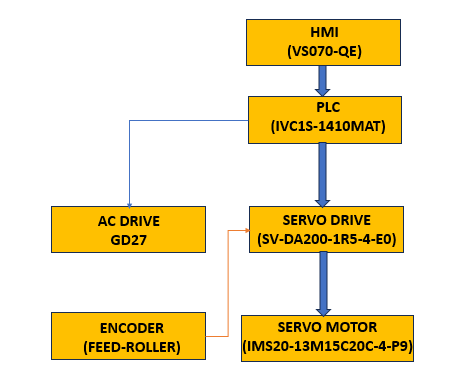

Figure – Machine flow chart with simple block diagram

2.1 Project information

* In this application different types of box and sizes cutting as per settings

* PLC: IVC1S-1410MAT, transistor outputs type PLC used for process execution

* Here 1.5kw servo used for cutter rotation as per feedback and cutting length

* Different speed and different types of sizes cutting

* Manual remote panels given for data feeding and access

* In PLC different type of cycle selection and execution function provide

* VS series HMI use for data setting, monitoring, and recipe function purpose.

2.2 INVT solution

Product | Specification/Model | Quantity |

PLC | IVC1S-1410MAT | 1 |

HMI | VS-070QE | 1 |

Servo Drive | SV-DA200-1R5-4-E0 | 1 |

Servo Motor | IMS20A-13M15C20C-4-P9 | 1 |

3. System commissioning

Figure – Machine front view and HMI setup

Figure – Panel photo and mechanical setup for servo as well as induction motors

4. Advantages and benefits

* In old system mechanic system use for box cutting of different sizes and manual power require more. In new system servo based ECAM function use to make system user friendly and smooth operation

* This solution is cost effective and easily we can implement where cost issue compares to Delta, Schneider, and other make automation system

* Accuracy too much high and speed also maintain as standard

* PLC and servo execution through pulse and communication mode as per requirements of operations.

5. Conclusion

As per study and application execution, these industries multiple type of machines for cutting boxes and many applications. We achieved result through implementation of simple cost-effective model of IVC series PLC and servo system. This application very useful for small and large industrial product manufacturing.

In this application we execute our system with 1 axis servo system with incremental mode. These types of application are popular and we provide best solution with minimum price. This type of system we can implement in many industries.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.