1. Project Background

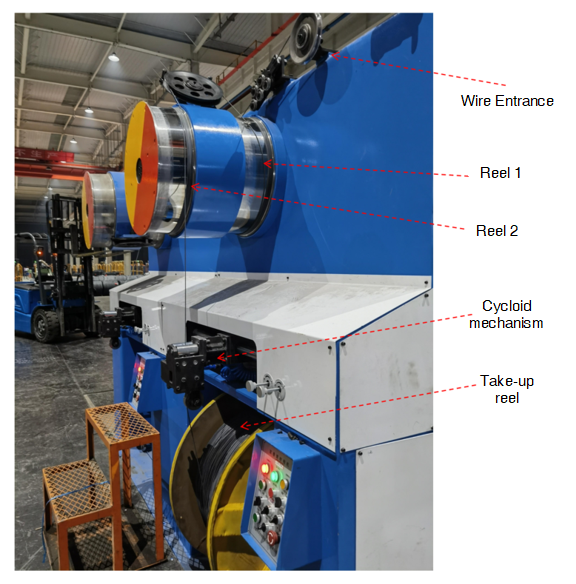

Double reel take-up machine, is a new type of double reel continuous take-up machine, in the wire and cable industry, the industry's double reel take-up machine is suitable for wire and cable reel take-up, it has a high take-up speed, in the process of changing the reel of the equipment does not slow down, no shutdown and so on. It generally consists of steel wire inlet, reel, reel holding mechanism, pendulum mechanism and so on.

2. Customer demand

Customer requirements in the wire and cable reel take-up process, single-axis non-stop application, workers change the line does not need to stop, and the operation is simple and convenient.

* wire entrance: wire process at the wire feeding equipment can not be stopped, otherwise a long time will burn the wire.

* the capacity of the roll mechanism: when the lower winding drum needs to be replaced, this mechanism begins to accumulate wire, this mechanism must be consistent with the speed of the drum 1, the accumulation of wire wrapped around the drum 1 and drum 2, began to accumulate wire. Note that this time the torque can not be too large, or pull the equipment, as well as the speed and drum 1 to maintain consistency; when the lower side of the winding drum replacement is completed debugging normal, the need to withdraw the line, the reeling mechanism reversed, the accumulation of wire back. At this time must maintain a certain torque, steel wire by a certain force or winding will be messy line.

* winding cylinder: to ensure that the torque control mode, the wire force remains unchanged, the speed can become larger!

3. INVT Solution

Based on the customer's demand, INVT provides the system solution of VS series HMI + TS600 series intelligent PLC + GD27 series inverter. The solution is characterized by easy winding and unwinding, high precision and so on.

4. Customer benefits:

The double reel take-up machine equipment program provides customers with the following benefits:

* Provide production efficiency: compared with the traditional spooling machine, when the workers replace the spooling reel, the operation is simple, one key replacement. For customers to achieve full automation of machinery, factory intelligence, 24 hours a day without stopping, etc.. Greatly improve production efficiency.

* Synchronous drive, accurate and controllable: GD27 products, torque control accuracy <5%, torque response time <10ms, low-frequency load capacity excellence, and taking into account the complexity of the operating state of the equipment synchronization and stability, you can keep the wire hauling speed and winding speed to match, to avoid the wire hauling process breakage or in the winding process of loose.

* Simplify transmission, simple maintenance: GD27 compact book line design, dexterity, small size, and GD27 support up to 150 motor cable applications, without the need for additional output reactor, optimize the electrical drive structure, for customers to save space and cost of cabinet.

* Flexible to adapt to different needs: suitable for heat treatment line, phosphating line and galvanizing line payoff and take-up, wire diameter 0.8~8.0mm.

* Easy to yield management and operation: this program is driven by frequency converter, PLC control, single head single control.

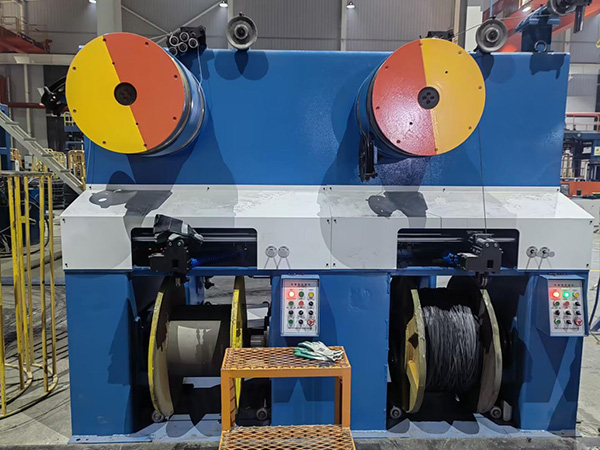

5. Field application pictures

6. Conclusion

Through a long time of stable and reliable performance, it has been proved that TS600+GD27 double reel equipment solution, in the cable winding industry, currently reaching the leading level in the industry, the equipment program is reliable, and the performance is better, more energy-saving and environmentally friendly, and has a high value of promotion. At the same time, INVT has a perfect after-sales service system, which can give customers great service guarantee.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.