With the implementation of policies related to energy conservation, consumption reduction, and the development of a low-carbon economy, the technological innovation system in the coal industry has been continuously improved and perfected. Coal enterprises urgently need to eliminate high-energy-consuming, high-pollution, and outdated production technologies, making rapid strides towards green and intelligent development.

1. Project Challenges

Mine hoisting is a key link in mine transportation, primarily tasked with lifting gangue, coal, and waste rock from underground, as well as transporting personnel, equipment, and materials. As crucial production equipment, mine hoists face significant issues such as high energy consumption, complex operational structures, and high danger levels. These issues not only affect the mine's production capacity and management but also concern the safety of every miner underground. Therefore, there is a need to improve the electrical drive requirements for mine hoist processes. Outdated technologies and equipment can no longer meet development needs, and they will be replaced by energy-saving, environmentally friendly, safe, and efficient fully digital production modes.

2. INVT Solution

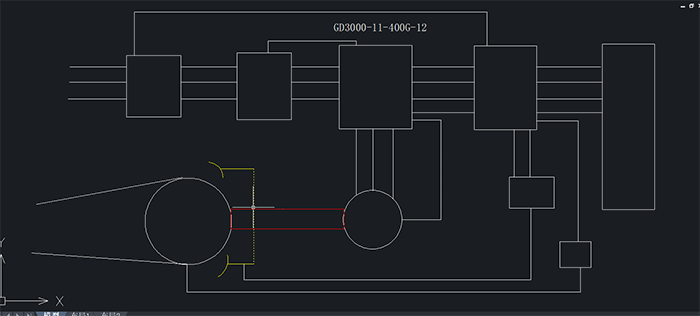

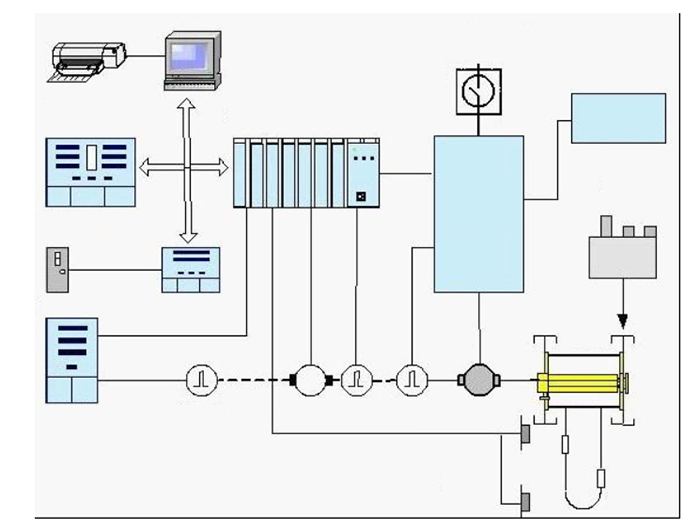

To meet the requirements for stable hoist operation and smooth four-quadrant operation, the ability to frequently perform forward, reverse, start, run, stop, and brake actions, and to run according to a specific speed profile, with the load being a constant torque load, INVT has introduced the GD3000 series inverter solution. This solution is designed for energy-efficient mine hoists driven by permanent magnet synchronous motors, enhancing the stability and comfort during operation, while also improving energy efficiency and the automation level of coal mines.

New Drive System Solution

Structure of Mine Hoist Control System

3. Customer Value

1. Strong Control Functions and High Reliability: The GD3000 series offers strong control functions and high reliability with excellent anti-interference capabilities. It ensures accurate stopping positions, facilitating loading and unloading.

2. Smart Mining Integration: Through fiber optic communication access to the underground ring network, operational status is transmitted to the central control room and displayed, realizing a smart mining environment.

3. Complex Operational Requirements: The solution meets the customer’s requirements for low-speed crawling, precise positioning, and high-torque lifting under complex working conditions.

4. Enhanced Safety: During start and stop processes, the impact on the mechanical system is reduced, thus enhancing safety.The application of INVT VFDs in the energy-saving transformation of mine hoists has improved the automation level and productivity of hoist equipment in the mining industry, played a very positive role in safe production, saved electrical energy, and genuinely reduced production costs for the mining industry, generating economic benefits.

On-Site Commissioning

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.