With the large-scale development of port equipment and offshore engineering equipment, the shipping industry is also growing, and the number of ships is also increasing. As a special transportation tool, ships need to be equipped with various equipment as supplements, among which marine Crane is an indispensable.

As an important part of the ship's equipment, marine cranes' technical level and performance are directly related to the ship's operating efficiency and ship transportation capacity. The traditional old-fashioned hydraulic system controlled grab crane cannot meet the requirements of fast, safe and stable equipment on site, and there is an urgent need for a crane. A new control method using a ship-specific VFD to realize the production and operation of grab crane lifting equipment.

Ship crane equipment technology and control requirements

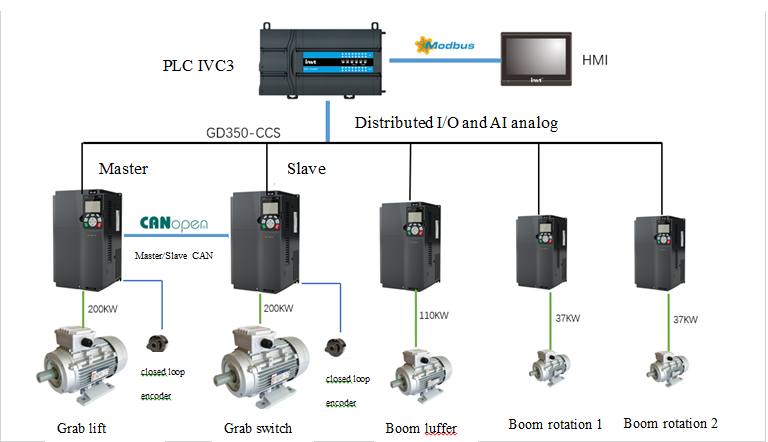

The on-site ship crane hoisting equipment uses the GD350-CCS ship-specific VFD plus a CAN communication expansion card to realize the master-slave synchronous control mode of the two inverters, so that the grab combined crane can respond synchronously and quickly, and maintain synchronous control of the opening and closing of the grab lifting.

Two 200kW VFDs control the lifting, opening and closing of the grab, one 110KW inverter controls the swing of the boom from 20° to 80°, and two 37KW inverters control the entire hoisting equipment to perform 360° operation.

Each process position controls the frequency output of the VFD through the host computer giving an external 4~20am analog current, and switches the master-slave control mode through the external IO input and starts and stops the inverter, and outputs the IO status of the inverter. Control the motor's brake release and closing and equipment fault protection.

The main process parts of the site have high requirements for the lifting and opening and closing synchronization of the grab crane. It is necessary to maintain the synchronization state of the grab crane in the master-slave linkage mode and the master-slave single-action mode to ensure that each group of steel grab cranes The rope is evenly stressed. To meet customer requirements, the equipment's safe load capacity is 30T, the empty bucket lifting and lowering speed is 60M/min, the boom luffing speed is 20M/min, and the rotation speed is 1.5R/PM.

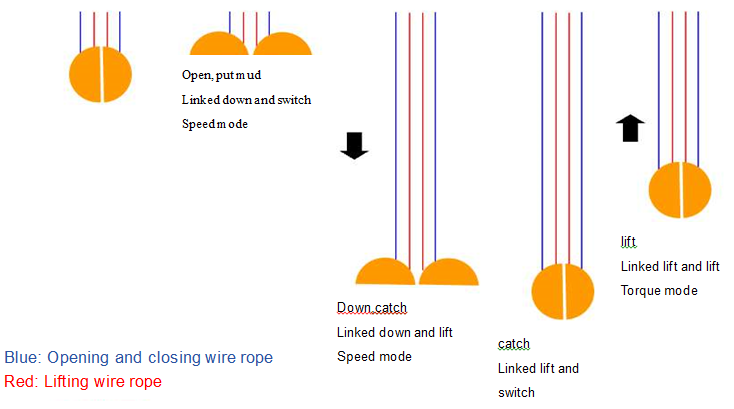

Equipment workflow diagram

Program features

1. GD350-CCS can realize master-slave linkage synchronous control, and can also switch to master-slave independent control mode through the external IO terminal function, realizing master-slave speed-speed mode switching to master-slave speed-torque mode;

2. The system uses CAN bus to control the action of the grab part of the hoisting equipment, which can achieve a rapid response of 60M/min for lifting, opening and closing the empty bucket of the grab, and ensures that the two sets of wire ropes of the grab crane are evenly stressed when lifting;

3. The system uses GD350-CCS inverter + encoder PG card to realize the motor closed-loop vector control method, which can achieve precise control of the motor's speed and position and ensure that the given motor speed is synchronized with the actual motor speed.

4. The system can realize various status feedback and self-diagnosis performance of the equipment through the GD350-CCS inverter status feedback signal, which greatly improves the safety and reliability of the electronic control system of the grab crane.

Scheme system diagram

Achieve the efficiency of catching and releasing materials 30 times/hour

The full frequency converter method controls various actions of the grab lifting equipment, achieving a safe load capacity of up to 30T for the grab lifting capacity, and achieving an efficiency of grabbing and releasing materials 30 times per hour. Compared with traditional hydraulic grab lifting equipment, the efficiency is improved. 30%.

CCS ship classification certification standards

GD350-CCS lifting special frequency converter complies with CCS ship classification certification standards, and the grab crane has higher safety, reliability and stable performance.

Extend equipment life

The lifting, opening and closing braking of the grab tends to be gentle, and the vibration and impact caused by acceleration and deceleration during the operation of the crane are effectively reduced, effectively extending the mechanical service life of the grab crane.

Summarize

The successful application of INVT's GD350-CCS lifting special frequency converter in marine 30T grab crane equipment fully reflects INVT's rich product range and stable

performance in the industrial automation product line. At present, the market demand for port and marine equipment continues to grow. INVT will continue technological innovation to create a highly efficient, safe and reliable ship equipment system and provide a more intelligent, large-scale, environmentally friendly and sustainable complete system solution for the industry. program to provide more choices and support for the upgrading and development of ship equipment

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.