1.All drive and all-around

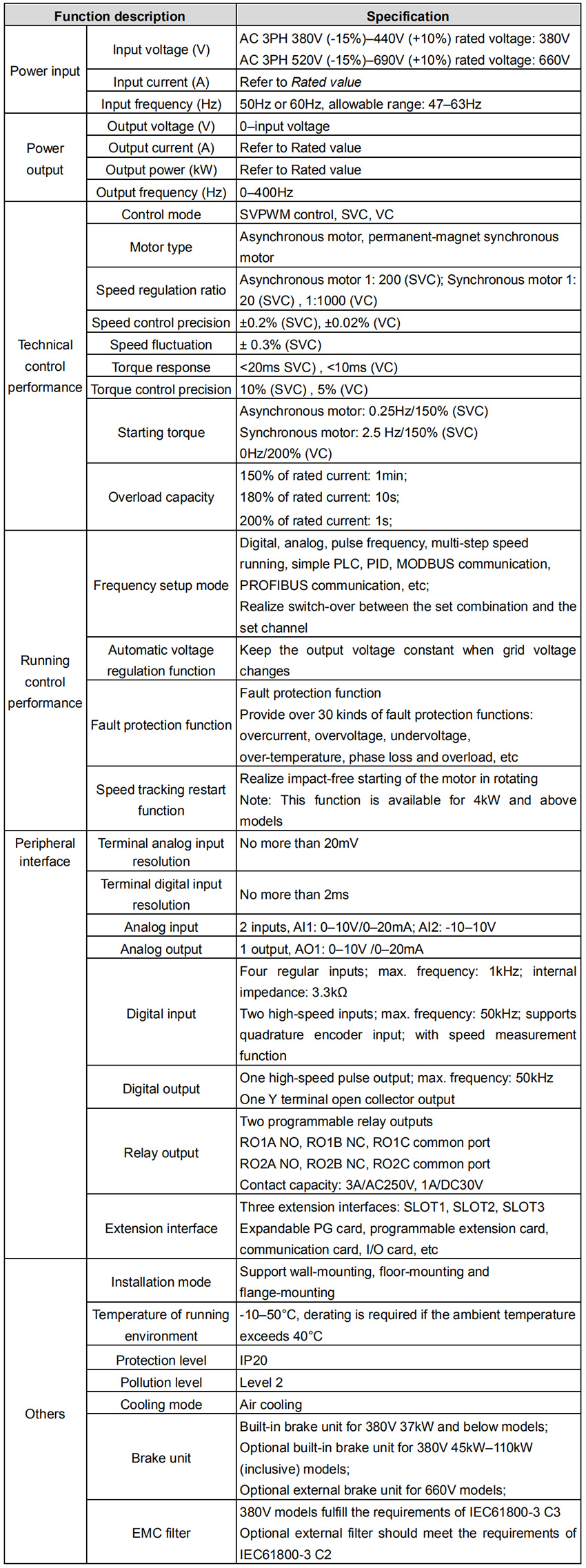

Support synchronous, asynchronous motor.

2.High extensibility

Optional PLC card, I/O card, communication card, PG card, etc. It can meet the needs of many kinds of expansion cards at the same time, which can satisfy the individual needs of customers quickly.

3.Support customer secondary development

4.Support multiple mainstream communication modes

Standard 485 communication

Support optional expansion card:Ethernet, CANopen, Profibus DP, Bluetooth, Profinet.

5.Wireless debugging

Bluetooth access, the use of mobile phone app instead of traditional keystroke keyboard, can be operated without opening electronic control cabinet, more comfortable application.

6.Material connection interworking, remote monitoring

Wireless access, easy access to the Internet of things and inverters can be operated through the mobile phone / computer, real-time understanding of the state of operation.

7.Standard USB interface, the program can be downloaded conveniently and quickly, and the operating curve of the inverter can also be recorded by external uplink, which is convenient for maintenance and analysis.

8.PG card adopts digital filter technology to improve electromagnetic compatibility and realize long distance stable receiving of encoder signal.

Compared with traditional scheme, the performance of anti-jamming is doubled.

9.Standard 2 HDI, can be used as speed source and can also support high-speed AB pulse input signal, which forms simple closed loop application to provide customers with a cost-effective closed loop application plan.

10.Built-in STO safety torque off function, in line with international standards, safer and more reliable application.

SIL2 level.

11.Standard LCD operating panel, supports 3 sets of inverter parameters upload and download, has the directory index function, may define the monitoring and the debugging parameters, extremely convenient debugging.

12.Maximum support 110kw power segment, built-in brake unit, cost and installation space savings for customers.

1.5~37kw: Standard built-in braking unit

45~110kw: Optional built-in braking unit.

13.18.5kw~110kw standard built-in DC reactor.

Application of INVT Non-woven Flat Mask Machine Control System

2020-09-18INVT AX70 PLC with EtherCat and GD350 series VFD used in sheet extruder machine

2022-08-24High Speed Automatic Folding Line Application

2022-10-18Application of INVT GD350 inverter in oil field pumping unit in China

2023-12-14INVT Solutions Help Achieve a 120 m/min High-speed Fully Automatic Folding Line

2024-08-01Application of INVTGD350 Series Inverter in the Casting and Rolling Mill

2025-01-06INVT GD350 VFD for Roving Machine Equipment Application

2025-01-14INVT GD350 Inverter for Stenter Setting Machine

2025-02-12

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.