1. Introduction

Most of China's oil fields are low-energy and low-yield, unlike foreign oil fields, which have strong self-injection ability. Most of the oil is pumped into the well by water injection and lifted from the formation by pumping unit (kowtowing machine). In China, replacing oil with water and electricity is the reality of oil fields at present, and power consumption costs account for a considerable proportion of China's oil exploitation costs. Therefore, in order to further improve the efficiency of pumping unit oil production system, save energy and reduce mining cost, it is particularly important to develop digital pumping unit. As the main equipment in oilfield development, the beam pumping unit is often used in the field, and there are still some disadvantages, such as the large difference between the operating parameters of the pumping unit and the parameters of the oil well, the mismatch between the equilibrium state and the working stroke of the pumping unit and the parameters of the oil well, which leads to the poor working state of the pumping unit and the low efficiency of the system. The research and development of digital pumping unit can make the pumping unit reach the best balance state according to the load of oil well, make the pumping unit work at a reasonable stroke frequency according to the liquid production of oil well, and effectively protect the pumping unit according to the working conditions of oil well; So as to maximize the consistency between the operating parameters of the pumping unit and the parameters of the oil well, give full play to the working ability of the pumping unit, and achieve the purposes of low-carbon development and energy-saving mining. In addition to the wellhead data acquisition, transmission and remote start-stop, the digital pumping unit also needs to realize the automatic parameter adjustment of the pumping unit and realize the real digital management and intelligent control.

2. The working characteristics of oil beam pumping unit

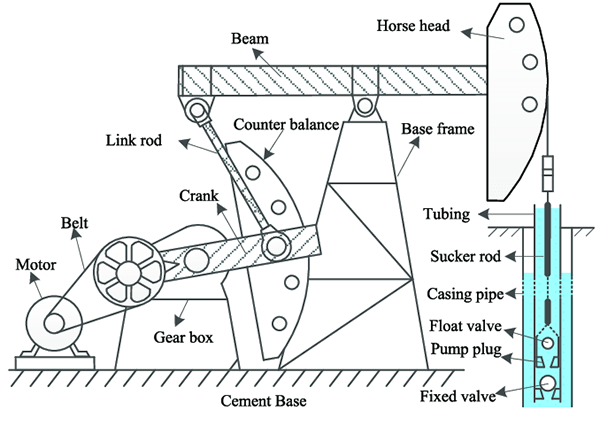

The beam pumping unit is mainly composed of four parts:

* Walking beam part: donkey head, walking beam, cross beam, tail beam, connecting rod and balance block (compound balanced pumping unit).

* Support part: central bearing seat, working ladder, retainer, operating table and support.

* Reducer: base, reducer cylinder seat, reducer, crank, counterweight, brake and other parts.

* Power distribution: motor seat, motor, distribution box, etc.

The motion of the beam pumping unit is to lift up and down repeatedly, once in one stroke, and its power comes from two balance weights with considerable weight driven by the motor. When the balance weights are lifted, the oil pumping rod is sent into the well, and when the balance weights are lowered, the oil pumping rod proposes to bring oil to the wellhead. Because the motor speed is constant, the load is lightened during the sliding block descending process, and the energy generated by the motor dragging cannot be attracted by the load, which leads the motor to enter the regenerative power generation state, feeding back the redundant energy to the power grid, causing the increase of the bus voltage of the main loop, which is bound to have an impact on the whole power grid, leading to the decline of the power supply quality of the power grid and the reduction of the power factor. Frequent high-voltage shocks will damage the motor, shorten the life of the motor and increase the maintenance amount.

On the other hand, in order to overcome the large starting torque, the motor used by the beam pumping unit is far greater than the actual required power, and the utilization rate of the motor is generally between 20% and 30% when working, and the maximum will not exceed 50%. The motor is often in a light load state, which causes a waste of motor resources. Moreover, the working condition of the pumping unit is continuously changing, which depends on the underground state. If it is always running at power frequency, it will inevitably lead to the waste of electric energy. In order to save energy and improve the working efficiency of the motor, it is necessary to carry out frequency conversion transformation.

3. The characteristics of variable frequency speed regulation of pumping unit

3.1 Frequency inverter speed regulation principle In order to solve the above problems, frequency conversion technology can be introduced into the control of beam pumping unit.

According to the motor theory, the speed formula is: n=60f(1-s)/P, where: p is the polar logarithm of the motor, s is the slip, f is the frequency of power supply, and n is the actual speed of the motor. It can be seen from the formula that the motor speed is approximately proportional to the frequency, and the motor speed can be smoothly adjusted by changing the frequency, so that the pumping speed of the oil extractor can be continuously changed. According to the working current of the motor, the working frequency of the motor can be determined, so that the stroke of the pumping unit can be conveniently adjusted according to the change of well conditions, and the purpose of saving energy and improving the power factor of the power grid can be achieved. At the same time, the variable frequency governor has many advantages, such as low-speed soft start, smooth and wide-range adjustment of rotation speed, complete motor protection functions, such as short circuit, overload, overvoltage, undervoltage and stall, which can effectively protect the motor and mechanical equipment, ensure the equipment to work at a safe voltage, run smoothly and reliably, improve power factor and so on, and is an ideal scheme for oil production equipment transformation.

At present, the more mature scheme of pumping unit energy saving is to transform its motor drive system with frequency inverter. Driving pumping unit with frequency inverter has the following three advantages: (1) The power factor is greatly improved (from 0.25 ~ 0.5 to above 0.9), and the power supply current is greatly reduced, thus reducing the burden of power grid and transformer and line loss. Frequency conversion transformation with the goal of improving power grid quality and reducing the impact on power grid. This is mainly concentrated in the occasions where power supply enterprises have high requirements for power grid quality. In order to avoid the decline of power grid quality, it is necessary to introduce frequency conversion control, and its main purpose is to reduce the influence of pumping unit working process on power grid. (2) The pumping speed can be dynamically adjusted according to the actual liquid supply capacity of the oil well, so as to achieve the purpose of energy saving and increase the crude oil output. (3) The "soft start" is realized, which avoids excessive mechanical impact on the motor, gearbox and pumping unit, prolongs the service life of the equipment and improves the production efficiency.

3.2 GD350 series high performance inverter introduction

Goodrive350 series inverter, which is a high-performance and multi-function inverter aiming to integrate the capability to drive both synchronous motors and asynchronous motors, and support torque control,

speed control, and position control. The inverter is armed with advanced vector control technology and the latest digital processor dedicated for motor control, thus enhancing product reliability and adaptability to the environment. The inverter adopts customized and industrialized design to realize excellent control performance through optimized functions and flexible applications. In order to meet diversified customer demands, the inverter provides abundant expansion cards including programmable card, PG card, communication card and I/O card to achieve various functions as needed.The programmable card adopts the mainstream development environment for customers to carry out secondary development easily,

fulfilling varied customized needs and reducing customer cost.The PG card supports a variety of encoders like incremental encoders and resolver-type encoders, in addition, it also supports pulse reference and frequency-division output. The PG card adopts digital filter technology to improve EMC performance and to realize stable transmission of the encoder signal over a long distance. It is equipped with encoder offline detection function to contain the impact of system faults.The inverter supports multiple types of popular communication modes to realize complicated system solutions. It can be connected to the internet with the optional wireless communication card, by which you can monitor the inverter state anywhere any time through mobile APP.The inverter uses high power density design. Some power ranges carry built-in DC reactors and braking units to save installation space. Through overall EMC design, it can satisfy the low noise and low electromagnetic interference requirements to cope with challenging grid, temperature,humidity and dust conditions, thus greatly improving product reliability.

4. Frequency conversion drag and system application scheme of oil beam pumping unit.

There are many problems in the practical application of variable frequency drive of beam pumping unit, which mainly focus on the treatment of energy generated by the power generation state of beam pumping unit.

4.1 Adopt common frequency inverter and energy consumption braking unit.

This method can be realized conveniently, but at the cost of more power consumption, which is mainly because the generated energy can not be fed back to the power grid. When the frequency inverter is not used and the motor is in an electric state, the motor absorbs electric energy from the power grid (the meter rotates forward); When the motor is in the power generation state, the motor releases energy (the meter is reversed), and the electric energy is directly fed back to the power grid, but it is not consumed on local equipment. The comprehensive performance is that the power factor of the power supply system of pumping unit is low, which has a great influence on the quality of power grid. However, the situation has changed when using ordinary frequency inverters. The input of ordinary frequency inverter is diode rectification, and energy cannot flow in the opposite direction. There is no path for the above-mentioned part of electric energy to flow back to the power grid, so it must be consumed locally with resistors, which is why the energy-consuming braking unit must be used.

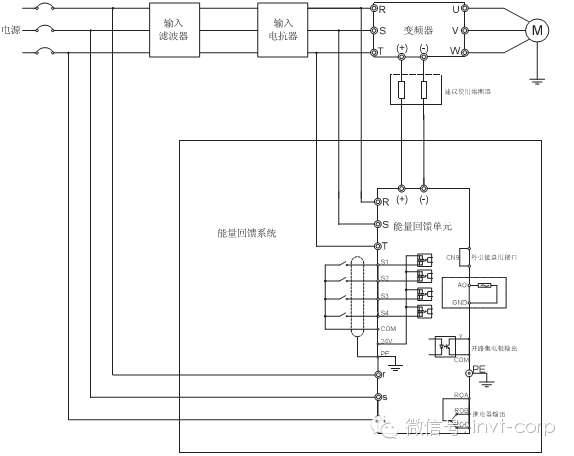

4.2 Inverter plus feedback unit control

In order to feed back renewable energy and improve efficiency, energy feedback devices can be used to feed back renewable energy to the power grid. Of course, in this way, the system will be more complicated and the investment will be higher. The so-called energy feedback device is actually an active inverter. According to the different power switching devices used, it can be divided into two types: thyristor (SCR) active inverter and insulated gate bipolar transistor (IGBT) inverter. Their common feature is that they can feed back the voltage of the DC circuit of the inverter to the power grid, as shown in Figure 1. The frequency inverter equipped with energy feedback unit is suitable for asynchronous motor with AC 50Hz and rated voltage of 380V, and realizes soft start, soft stop and speed regulation operation process control. It has the advantages of small starting current, stable speed, reliable performance and small impact on power grid, and can realize arbitrary adjustment of up and down speed and closed-loop control operation; Users can determine the punching machine, speed and liquid production of pumping unit according to the liquid level and pressure of oil well, so as to reduce consumption and save energy and improve pump efficiency; Reduce the wear and tear of the equipment, prolong the service life, save energy with high efficiency and low cost, and realize the automatic operation in the state of maximum energy saving.

Wiring diagram of frequency inverter plus feedback unit

5. Customer income

The indicator diagram of the pumping unit tested in the oil field shows that the digital pumping unit composed of Goodrive350 frequency inverter runs well and the pumping unit works in the best state. The solution using Goodrive350 frequency inverter as control has the following advantages in the application of digital pumping unit:

1. The frequency conversion solution can make the pumping unit reach the best balance state according to the load of the field oil well, make the pumping unit work at a reasonable stroke according to the liquid production of the oil well, and effectively protect the pumping unit according to the oil well working conditions; So that the operating parameters of the pumping unit are consistent with the parameters of the oil well to the maximum extent, and the working ability of the pumping unit is brought into play to realize low-carbon development and energy-saving mining.

2. The built-in communication function of frequency inverter provides RS485 communication interface, which makes the communication connection with RTU control module easier.

3. Modular design makes the maintenance of the system easier.

4. The frequency inverter has a variety of protection and fault output functions, such as short circuit, overload, overvoltage, lack of phase and stall, which can effectively ensure the safe and efficient operation of the system.

5. The parameter adjustment and management requirements of the frequency inverter can be effectively realized through the station control platform, and the real unattended well site can be realized. In 2012, an oil production plant in Shengli Oilfield used 135 electromagnetic speed regulating motors with energy feedback. It is tested that the average active power saving rate per ton of liquid is 32%, the average reactive power saving rate per ton of liquid is 43%, the power factor is increased by 0.21 on average, and the comprehensive power saving rate is 35%. The annual power saving capacity is 4.56 million kWh, and the annual power saving benefit is 3.2 million yuan. The following picture shows the frequency inverter system of the field pumping unit.

6. Concluding remarks

In addition to the wellhead data acquisition, transmission and remote start-stop, the digital pumping unit also realizes the automatic parameter adjustment of the pumping unit, which minimizes the labor intensity of front-line employees and reduces the total employment of front-line employees, making the well site equipment unattended. As the power drive equipment of digital pumping unit, Goodrive350 inverter has a good application in digital pumping unit with its advantages of high efficiency, low noise, large starting torque, high reliability, good speed regulation performance and maintenance-free. The actual operation proves that this control system is stable, which further improves the efficiency of pumping unit oil production system, saves energy, reduces the production cost, and realizes the economic and effective development of oil fields and the real digital management and intelligent control.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.