1. Project Background

Originally, in the process of lifting and lowering tubular columns on oil rigs, when the load is large, it is necessary to use double-hanging rings to cooperate with the operation, in this case, if the driller and the wellhead operator do not concentrate or do not cooperate properly, it is very easy for single-hanging ring accidents to occur when lifting the drill.

As a result, the intelligent control system for double-hanging-ring operation was born. Intelligent control system for double chuck operation is to detect the working status of chuck and travel hoist system through sensors and winch encoders, as well as to monitor and judge the torque of the winch, so as to ensure that the drill driver cannot carry out the drilling operation when the chuck is not inserted. That is to say, under the drilling condition of double hitch operation, if the hitch pin is not inserted (or not inserted in place), the system can automatically limit the torque output of the winch, so that the hitch cannot be pulled, thus avoiding the occurrence of single-hitch accidents from the root.

2. Customer Requirements

Drilling rig ring intelligent protection device using independent PLC control, touch screen display and set parameters, requires PLC small size, stable and reliable control, especially for the encoder signal counting to be accurate, drop power can be maintained, can reset the count value, can be pre-designed values, etc., to ensure that the encoder to measure the accuracy of the position of the big hook, to ensure that the big hook zero positioning interval is accurate, the error is within the permissible range.

3. INVT Solution

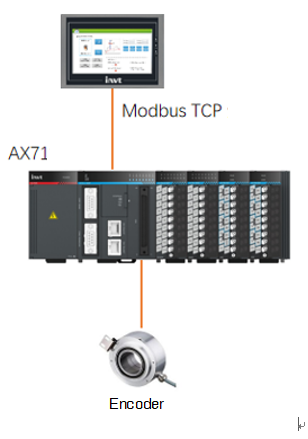

Based on customers' needs, INVT launched the solution of VK series high-quality HMI + AX series medium-sized PLC products on the intelligent protection device of drilling rig rings.

The solution supports IEC61131-3 programming system, IL, LD, FBD, ST, SFC, CFC six standard programming languages, 200 kHz high-speed I/O, EtherCAT, CANopen, RS485, Ethernet communication interfaces. At the same time, PLC products have a small size, stable and reliable control, accurate counting, counting value can be maintained when the value is dropped, can reset the counting value, can be pre-designed value, etc., to fully meet the needs of customers.

4. Solution Benefits

* In terms of safety: Through the high-speed pulse counting channel, the encoder return value for measuring the position of the big hook is counted accurately, and the data such as winch torque monitoring is used to comprehensively judge the next reliable action of the equipment, which effectively avoids accidents caused by improper manual judgment.

* Flexibility: AX71 programmable controller integrates 16 200kHz pulse inputs, supporting single-phase or A/B-phase high-speed counting.

* In terms of convenience, AX71 PLC has a rich library of high-speed counting function block instructions, including counter settings, count value reading, latch, preset value, pulse width measurement, timing sampling, count value comparison, etc., through the function block call, programming efficiency is greatly improved.

* In terms of reliability, high-speed counter input channel with filtering parameter setting function, through the setting of the parameter to improve the signal's anti-interference, to ensure the accuracy of the counting, and at the same time with the data value of the power failure can maintain the function, to ensure that the position of the big hook accurate judgment.

5. Summary

With the development of industrial control technology, the electric control system of oil rig equipment is more intelligent and safe. After on-site use verification, INVT control system solutions have the ability to realize the control requirements of high efficiency, high precision, safety and reliability.

In addition, INVT has system solutions and practical applications in various aspects of oil drilling, mining, transportation, refining and processing. In the future, INVT will continue to research and develop new technologies to help the petroleum industry develop technologically.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.