Recently , an offshore drilling platform in Bohai officially started working with the help of INVT variable frequency power supply . This giant "drilling rig" will start to dig from Bohai , and the system has significant power saving effect and good operation effect.

Focus on bottlenecks of project, Achieve innovation in key drilling R&D

Traditional drilling platforms use diesel generators to provide electricity for drilling equipment. Living and working share a power system , which has problems such as mismatched operating power, serious environmental pollution, and low automation. In recent years, the price of diesel has continued to rise, increasing the cost of oilfield drilling operations.

On a drilling platform in the north , the original system was equipped with 5 Carter 3516 generator sets, the system power system was 690V/ 60Hz , and the main load equipment included 3 mud pumps (1150HP*2/unit) , 3 drilling winches (1150HP*3) , 1 top driver (1150 HP *1) , auxiliary pumps and life power supply . Now it is necessary to install a set of variable frequency and voltage power supply device to realize the power supply of the drilling platform through the oil production platform , and realize the shutdown of the generator set of this platform and the power supply and management of the power grid.

The “eyes” and “brains”of drilling platform

Making deep-water drilling safer and more efficient in the ocean

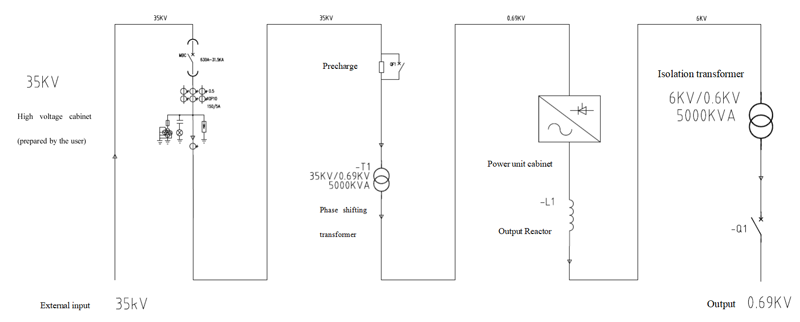

According to the on-site requirements, in order to ensure the stability and reliability of the power supply of the drilling platform, INVT adopts the configuration solution of GD5000 power supply dedicated inverter + medium voltage precharge, and optimizes the step-down transformer, phase shift transformer and control transformer into one, which greatly saves the layout space and provides the possibility for the successful implementation of the solution. INVT drive solution comprehensively improves the on-site production efficiency and ensures the safety of on-site operations, and has the following excellent features:

1. High power factor, "perfect" harmonic-free, no need for additional reactive power compensation and harmonic control devices , reducing noise pollution.

2. Reduce the impact on the power grid, extend the service life of equipment and improve production efficiency.

3. It has multiple protections such as overcurrent, short circuit, overvoltage, undervoltage, and phase loss, has strong ability to adapt to power grid fluctuations, and has a wide voltage operating range .

4. High-speed DSP chip, high control accuracy, fast response speed, strong anti-interference ability, and complete fault diagnosis and protection functions .

5. Simple operation, easy operation, remote setting or monitoring of operating parameters, and intelligent adjustment.

Significantly reduce the cost of oil and gas field development, An important tool for efficient development of marine oil and gas resources

According to the statistics of completed drilling operations: nearly one million yuan can be saved every month

Consumption before transformation | Consumption after transformation |

9m³ x¥8000 x 45 days≈ ¥3,240,000 yuan | 1606860kWh x 1.2yuan/kWh ≈¥1,930,000yuan |

According to the statistics of completed drilling operations: the application of shore power in 45 days directly saved 1.31 million yuan in economic savings , and the energy-saving effect is very obvious. The power system that can realize dual power supply of platform shore power and diesel generator is upgraded to a digital, intelligent and information-based drilling power supply system . It is efficient, energy-saving and environmentally friendly, bringing good economic and social benefits to oilfield operations .

The petroleum and petrochemical industry has entered the era of intelligence, and The "magic mahcine" are constantly being updated. In addition to continuing to exert its strength in general applications such as pumping units, submersible electric pumps, water injection pumps, oil transfer pumps and other traditional applications, INVT also has typical application performance in high-end applications such as oilfield drilling rigs, such as mud pumps, winches, rotary tables, top drives and other load types.

In the future, INVT will continue to deepen its roots in the oil industry and contribute its own strength to the country's oil industry.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.