1. Background

In recent years, with the development of the roving industry and the maturity of China's roving technology, the dependence on imports has become less and less. Since 2018, the export volume and amount of China's roving have continued to grow, while the import volume and amount have declined rapidly.

As a pillar industry and livelihood industry of my country's national economy, the textile industry is facing realistic problems such as the disappearance of the demographic dividend, increasing environmental pressure, and intensified external competition. On the basis of improving the manufacturing quality and reliability of spinning machinery, automation and continuity are the general trends in the development of spinning machinery and equipment.

2. Brief introduction of roving machine

The roving machine is mainly composed of feeding, drafting, twisting, winding and forming parts. Its main function is to make fiber strips into roving spinning machines, and wind the roving into certain packages to meet the requirements of roving machine processing. In addition, in order to ensure the output and quality of the product, the roving machine also has some auxiliary mechanisms, such as cleaning devices, photoelectric automatic stop devices, and traditional roving machines also have anti-detail devices and tension compensation devices.

3. INVT solution

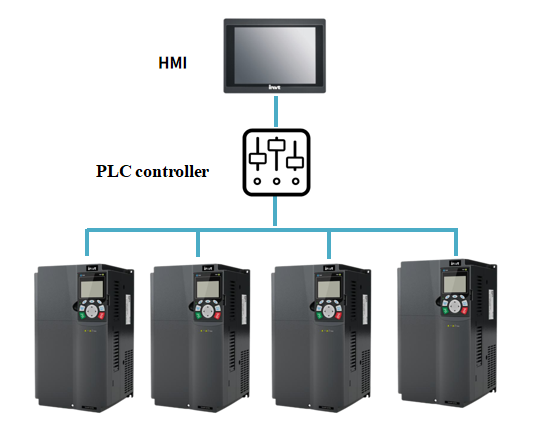

In order to continuously update the roving technology and improve product performance, INVT launched the HMI+PLC+GD350 series VFD solution. The system uses the PLC controller to send enable, speed and other commands to GD350 through bus communication. The GD350 VFD integrates synchronous motor drive and asynchronous motor drive control logic, and integrates torque control, speed control and position control.

GD350 adopts technologically advanced vector control technology and the latest motor control dedicated digital processor, while strengthening the product's reliability and environmental adaptability as well as customized and industry-oriented design, optimized functions and flexible applications. It can achieve efficient and stable production of fiber strips into roving, and wind the roving into a certain package to meet the requirements of roving machine processing.

4. Customer benefit

1. High speed accuracy: accept the speed given by the host computer bus, and the speed stabilization accuracy is high.

2. Process parameter preservation: after all process parameters are confirmed, they can be stored and saved in the PLC and directly called.

3. Tension control: unified setting through the human-machine interface, can be adjusted online. The tension is balanced and consistent, and the tension accuracy is high.

4. Reciprocating control: high yarn guide accuracy and perfect molding.

5. Length/winding diameter setting: the winding length or winding diameter can be set, with advance warning and full winding alarm prompt functions.

6. Photoelectric automatic stop function: timely alarm stop for wire break detection, safety protection, prevent misoperation, and protect the personal safety of operators.

Onsite pictures

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.