Abstract: This paper mainly presents the INVT AX-70 series PLC and DA200 servo drive used to spread the fabric as per the requirement of user. In this project, HMI is used for data feeding and monitoring of the process.

Keywords: AX-70 series PLC, VS-Q HMI, DA200 servo drive, Textile industries, encoder, textile Spreader Machine.

1. Introduction

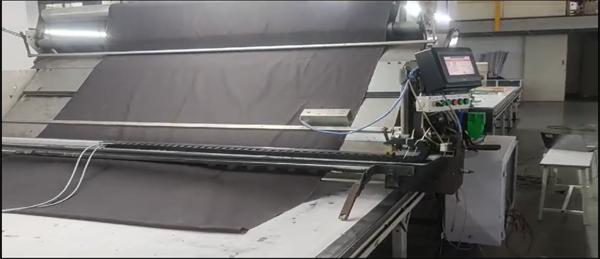

The major parts of the machine are 3 Encoder, servo drive and motor, AX-71PLC and HMI.

1) PLC and HMI: PLC is utilized in this application to manage the entire machine application. Setting length of fabric, quantity of fabric, monitoring, cycle start/stop, manual operation, system settings, parameter adjustments, and user-defined activities are all done with HMI.

2) 3 – Encoder: 2 encoder is measuring the length of fabric at bed side. And one encoder is located at feeder side of fabric measurement.

3) Process: On the top side fabric role is placed and that role is driven by the servo system with encoder feedback. User insert the length of fabric and the quantity of fabric in HMI. And then give start command. As per the fabric length input top moving part come forward as per length. Then after reaching at length servo system starts dispensing fabric on the bed and length of fabric is measured by the encoder system. At the time of dispensing the fabric, top moving part goes in reverse direction. After require length of fabric spread on bed, cutter cuts the fabric. And cycle repeats till quantity of fabric completes. Top moving part is driven by INVT drive and motor system.

2. Project information and Solution

Figure – Machine front view with user console and trial setup

* Project information

- This is the best auto spreader for quantitively production.

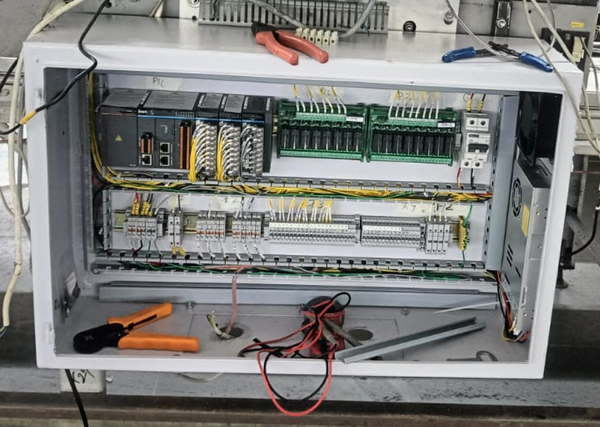

- PLC: AX71 transistor outputs type PLC used for process execution

- 3 encoder is used for feedback. And measurement of fabric length.

- we can vary the size of spreading fabric. And we can spread the fabric quantity as per our requirement.

- There is auto cutting system. after fabric is spread as per requirement cutter cut the fabric.

- One VFD is used for unwinding the material.

* INVT solution

Product | Specification/Model | Quantity |

PLC | AX-71-C-1608N | 1 |

HMI | VS-070HE-1 | 1 |

Servo Drive | SV-DA200-1R5-4-E0 | 1 |

Servo Motor | IMS20A-10M15C30C-4 | 1 |

VFD | GD20 | 2 |

* System commissioning

• Nowadays in textile industries all the manufacturer are doing work in quantity. So, what happened if they use this machine production is become faster and easier.

• For this fabric spreading they specially required man power for spreading. But by using this machine only single operator can also do the task of multi person.

• In auto mode machine can also spread the fabric by its own so that doesn't require any man power.

5. Conclusion

As per the application execution we get to know about the industries that are still behind from time via technology and time. So, giving them this solution makes them faster reliable and efficient in their work.

6. Future Scope

Many manufacturers are there which are still using the traditional man power work for fabric spreading. So ultimately, they are wasting many moneys, manpower, and working hour. If we give them this solution that saves many things and make work faster, cheaper and accurate with time saving.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.