1. Project Background

As the demand for aluminum products expands across various sectors—driven by lightweight requirements for energy storage and power batteries, packaging needs in food, furniture, pharmaceuticals, and daily items, as well as the lightweight trend in transportation industries such as automotive, rail, aviation, and maritime—the necessity for aluminum is set to rise further. In casting and rolling production lines, inverters play a pivotal role, regulating motor speed and torque to ensure precise control throughout the production process.

2. Customer Requirements

* Closed-loop control to maintain accurate speed with minimal torque output fluctuation.

* Synchronized speed for both the upper and lower main drive rollers.

* Constant tension control for the coiling mechanism, even under no tension feedback conditions.

3. INVT Solution

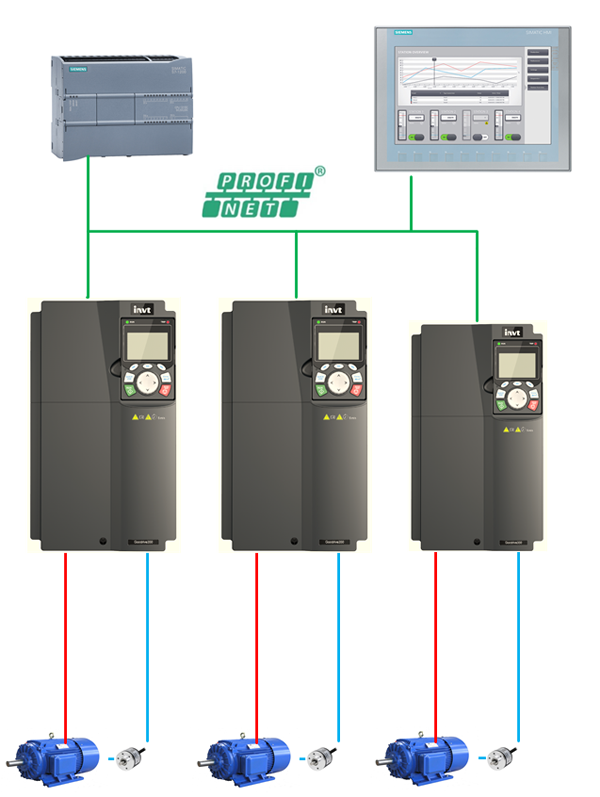

INVT has introduced a solution comprising the GD350 series inverter, PN communication card, and PG card. The GD350 series inverter offers several advantages:

* It integrates rapid expansion with flexible networking, enhancing scalability while catering to individual customer requirements.

* It incorporates control for speed, torque, and position within a single unit.

Standard configuration includes an STO (Safe Torque Off) function, enhancing application safety.

* The PG card employs digital filtering technology to ensure stable reception of encoder signals over long distances.

System Topology Diagram

4. Customer Benefits

1. High Reliability: Closed-loop control for the upper roller, lower roller, and coiling mechanism provides precise control of speed and torque.

2. Cost Reduction: Integrated energy-saving control algorithms effectively minimize operational losses of load motors, thereby reducing running costs.

3. High Stability: The coiling mechanism employs constant tension control, resulting in more consistent product quality.

4. Enhanced Safety: The built-in STO function promotes a safer operational environment.

5. After-Sales Service: INVT provides professional technical support and timely after-sales service, ensuring effective resolution of equipment operation and maintenance issues.

5. Conclusion

The successful deployment of this casting and rolling mill exemplifies INVT's automation solutions, which enhance equipment stability, production efficiency, and product quality through automated control and optimized production line performance, earning high praise from clients. INVT is committed to developing electric drive product solutions, leveraging extensive automation product lines and market experience, and will continue to advance in line with technological developments in the industry.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.