1. Project Background

With the escalating demand for galvanized products across various industries—such as petroleum, chemical, pharmaceutical, aerospace, dyeing, and hot-dip galvanizing—there is widespread application in sectors including wire, structural components, standard parts, ductile iron components, steel towers, and sheet metal. In galvanizing production lines, servo systems serve as critical equipment, regulating equipment positioning, speed, and torque to achieve precise control during the production process. Moreover, they offer significant benefits in energy savings, ecological sustainability, reduced consumption, diminished labor intensity, and extended equipment lifespan, thereby effectively enhancing product quality for clients.

2. Customer Requirements

* Support for PROFINET high-speed industrial bus.

* Capability for high torque output with robust overload capacity.

* Accurate equipment positioning to ensure the precise alignment of ten galvanizing baths, thus ensuring normal operational performance.

3. INVT Solution

INVT has introduced the DA200-F0 series servo solution, which boasts several advantages:

* A 23-bit high-precision encoder enhances positioning accuracy, ensuring smoother processing at low speeds and yielding a glossier surface finish.

Speed observation and load inertia identification significantly improve trajectory tracking precision.

* Triple overload capability delivers powerful performance.

* Support for PROFINET, EtherCAT, Modbus, and CANopen high-speed industrial buses.

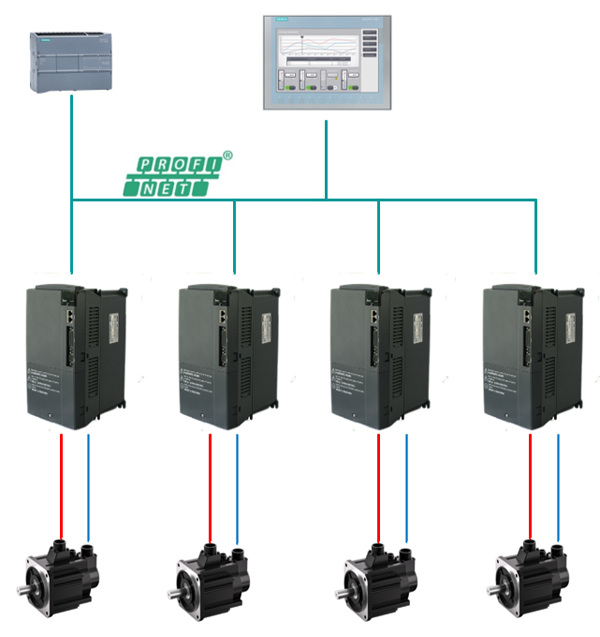

System Topology Diagram

4. Customer Benefits

* High Reliability: Closed-loop control for the upper roller, lower roller, and coiling mechanism ensures more precise speed and torque control.

* Cost Reduction: Integrated energy-saving control algorithms effectively minimize operational losses of load motors, thus reducing operating expenses.

* High Stability: The coiling mechanism utilizes constant tension control, resulting in more stable product quality.

* Enhanced Safety: Built-in STO (Safe Torque Off) function promotes safer operation.

* After-Sales Service: INVT provides expert technical support and timely after-sales service, effectively addressing equipment operation and future maintenance issues.

5. Conclusion

The successful implementation of this machinery is a testament to INVT’s automation solutions, which enhance stability, production efficiency, and product quality through automated control and optimized production line efficiency, receiving high acclaim from clients. INVT remains committed to developing electric drive product solutions, backed by extensive automation product lines and market experience, and will continue to advance in alignment with industry technological developments.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.