1. Project Background

Folding line equipment is the core equipment for producing paper. It is used to process roll-type raw paper into strip-shaped paper, also known as paper machine. Used in high-speed scenarios to ensure folding neatness and achieve high position accuracy and high speed accuracy. At the same time, the consumer demand for easy extraction of the first half discount requires intelligent and flexible switching of processes between various process actions, and close connection during operation.

In the past, the folding line market was dominated by solutions from overseas brands. However, with the rapid development of the market and the increase in consumer demand, more and more companies have begun to choose domestic brands, taking into account production capacity upgrades, process improvements, and cost control

2. Equipment Principle

* Feed paper: The main roller is controlled by a VFD.

* Cutting paper: The main roller is divided into a front paper feeding roller and a rear paper feeding roller. Each roller has 3 knife edges evenly distributed, that is, each roller rotates once to feed 3 sheets of paper, a total of 6 sheets.

* Paper Joining: First, the front paper is separated and the front lift is used to pick up the paper. The synchronization ratio between the front lift and the spindle is converted according to the thickness.

* Tail folding: The paper is separated from the back and the tail is folded up and down. Since the rear lift is below the front lift, during the paper picking process of the front lift, the rear lift synchronizes with the lower speed of the front lift to avoid collision.

* Handover: After reaching the set conditions, the receiving platform takes over the paper connection, and the synchronization ratio between the receiving platform and the spindle is converted according to the thickness. Since the receiving platform is below the rear lifting platform, during the rising process of the receiving platform, the rear paper separation and rear lifting steps must be avoided to avoid collision.

* Paper separation: After the paper receiving platform reaches the set specifications, it will switch back to the front paper separation and front lift paper receiving.

* Paper output: While the front paper is separated and the front lifting paper is connected, the receiving table lowers the processed strip paper onto the conveyor belt.

3. INVT Solution

The original plan of a packaging printing customer in Foshan City, China, used a pulse servo solution, but there were problems such as low efficiency, complicated wiring, and difficulty in upgrading and transformation. The requirements were as follows:

* Adopting EtherCAT communication to replace pulse input to improve efficiency, the desired target is 120 m/min.

* Adjust the process timing through HMI human-computer interaction.

* The servo axis speed is synchronously related to the paper feed axis speed.

Therefore, the folding line solution of AX71 series PLC + DA200 EtherCAT bus servo driver + GD350 series VFD + VS070HS HMI launched by INVT makes extensive use of electronic gear functions and achieves high-speed folding paper separation and folding tail flipping through multi-axis composite synchronization functions.

3.1 Characteristics of INVT solution

* Powerful composite synchronization control:

In the paper joining process, the front lifting and encoder shaft are synchronized;In the tail folding process, the rear lifting and front lifting are synchronized;

In the handover process, the front lifting and encoder shaft synchronization is switched to the receiving table and encoder shaft synchronization.

* The timing of the process can be modified through the "number of trigger pieces" to adapt to actual on-site needs.

* The speed of the process can be modified through the "number of process pieces" to correlate the main axis speed.

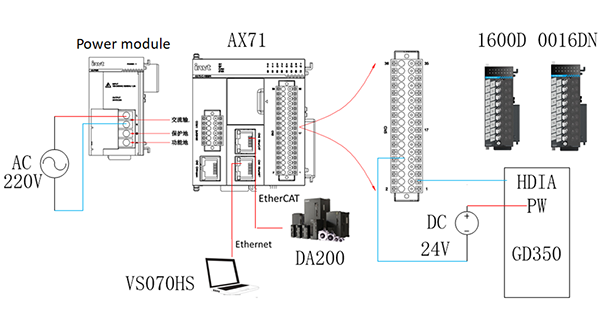

3.2 System schematic diagram

3.3 Solution configuration

Type | Product series | Quantity | Description |

Controller | AX71-C-1608N | 1 | Based on Codesys platform |

Digital output module | AX-EM-0016DN | 2 | Control cylinders, solenoid valves and other electrical components |

Digital input module | AX-EM-1600D | 1 | Detect electrical components such as sensors and buttons |

HMI | VS070HS | 1 | 7 inch |

Servo drive | DA200 series | 6 | EtherCAT model, They are: passive encoder servo, front paper separation, front lifting, rear paper separation, rear lifting and receiving table. |

VFD | GD350 series | 1 | Paper feeding host |

The paper feeding host VFD completes paper feeding and cutting, and is connected to the passive encoder servo through a coupling. The position speed of the passive encoder servo is equal to the position speed of the host VFD. The front paper separation servo and the front lift servo complete the paper splicing and paper separation, the rear paper separation servo and the rear lift servo complete the tail folding, and the receiving table servo completes the handover, cooperation with paper separation and paper output.

3.4 Advantages of INVT solution

* Efficiency

The maximum processing efficiency is 120 meters per minute, or 14 strips per minute.

* Product

The EtherCAT bus servo driver DA200 has simple wiring and beautiful electrical cabinet layout.

DA200 is used for identification in the program, which facilitates model change and eliminates the need to frequently modify the program.

The programming platform is Codesys, with rich programming languages, making it easy to realize control requirements and upgrades.

* Process

Streamlined process parameters facilitate on-site debugging. Improve stability and accuracy with passive encoder servos. Independent encoders often suffer from many inconveniences such as complicated wiring, poor anti-interference ability, and the inability to directly participate in multi-axis linkage.

* Cost

The front frame, nose and rear frame can be controlled separately through communication and interaction, or they can be controlled integrated to effectively manage costs.

4. Field application pictures

5. Conclusion

This solution has multiple advantages such as high efficiency, intelligent process, convenient upgrade and transformation, and complete after-sales support system. INVT has very rich experience in the printing and packaging industry. In addition to folding line solutions, it also has complete line solutions such as paper cutter solutions, single charter machine solutions, medium charter machine solutions, and rewinding and sealing line solutions to help partners develop together.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.