Abstract: Test benches for different parts of powerful vehicles are the most important part for development and production of industrial vehicles. This article introduces a successful application case of GD800 low voltage drive (VFD) as test bench for transmission of industrial vehicles

Keywords: transmission, GD800, bench.

1. Forewords

Transmission test bench is one of the most important part of industrial vehicles development, design and improvement.

This test bench allows testing reliability, rigity, power and capacity of vehicles transmission in such modes as:

* Vehicles start from zero speed

* Uphill moving of the vehicles

* Movement with Different speed controlled by automatic transmission switching.

This test bench also allows to obtain main performance of vehicles transmission as: torque. Customer can monitor the torque of transmission in a real time and simulate different situations (shown above) to research behavior of transmission.

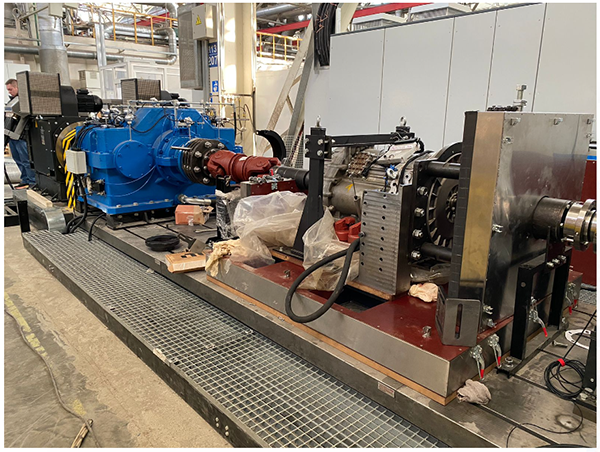

Figure 1 – test bench

2. Project introduction

2.1 Device informaiton:

Motor parameters | |

Two Asynchronous motor for 560 kW | |

Motor type | Asynchronous motor |

Rated power | 560 kW |

Rated voltage | 400 V |

Rated current | 971 A |

RPM | 4000 |

One Asynchronous motor for 638 kW | |

Motor type | Asynchronous motor |

Rated power | 638 kW |

Rated voltage | 400 V |

Rated current | 1061 A |

RPM | 2600 |

VFD parameters | |

Model | GD800-26-0630-4 (multi drive) |

Rated power | 630kW |

Rated voltage | 400V |

Rated current | 1200A |

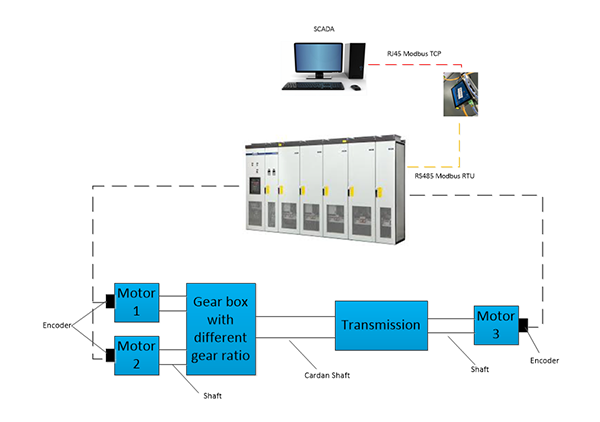

2.2 Functional block diagram of system main circuit:

Figure 2 Functional block diagram

Figure 2 Functional block diagram

2.3 Scheme description:

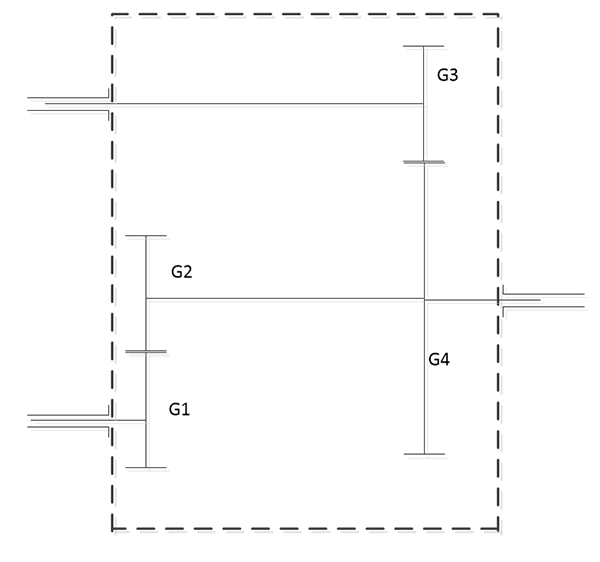

The VFD is connected to the three motors worked in closed loop control mode with encoders. Motors №1 and №2 connected to the gearbox. Motor №2 what connected to the gear box has higher gear ratio than motor №1. Motor №1 is connected to the small gear what directly connected to output main gear of cardan shaft.

Figure 3 – gear box ratio

Motor NO.1 , No.2 and gear box are used to imitate back main car rear drive axle. This system used as load for transmission box. Closed loop control allows customer to imitate the load in torque control and speed control modes.

Motor NO.3 is used as main motor of the vehicle. It also works in closed loop control. Motor NO.3 tries to rotate motor 1 and 2 via transmission what provides torque. This torque customer can monitor in a real time and research behavior of transmission.

2.4 VFD system advantage:

- Significant energy savings through optimized process control.

- AFE rectifier provides low level of THDi, THDu.

- AFE rectifier provides energy regeneration to the grid.

- The motor starts smoothly without impact, extending the life of the equipment.

- Closed loop vector control provides precise torque control and load of test bench

- Comprehensive protection functions: overvoltage, overcurrent, overload, phase loss, overheating, etc.

- Reduce mechanical maintenance work.

3. Field site photos

Figure 4 - Field site photos

4. Conclusion

The use of GD800 as a test bench of vehicle transmission gives a good opportunity to research different phenomenon of transmission behavior under the different condition.

The GD800 provides good capacity, power and performances for such application. It helps reduce energy consumption in vector control mode and increase efficiency of vehicles transmission tests.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.