1. Project background

PQF pipe mill means premium quality finishing seamless steel pipe mill, which is the most advanced limited motion mandrel pipe rolling mill. Using three-roll frame overcomes the disadvantage of traditional two-roll frame. Make the hole type closed better.It has innovation in process control and presents the highest level of hot-rolled tubes manufacturing.

2. Customer requirements

Ansteel Seamless steel pipe factory φ177PQF pipe mill was put used in 2007. With an annual production capacity of 200,000 tons. Product specification is φ73-180mm*5-16mm.

The original drive system of the unit used a regenerative rectifier and high-power inverter from an international brand. The rolling mill group consists of five drive sets, including 15 rolling mills, 4 limited-speed motors, 4 tube-removal motors, and 3 VRS motors. This trial machine is replacing the #2 set with the largest rolling load, which includes three 600kW motors. The original inverter specification was 11K7, designed for heavy-duty power of 1060kW, 1100A; control was achieved via Profibus-DP by a PLC.

Due to the upgrade and transformation of the 177 production line, the requirements for the continuous rolling mill have been further increased, requiring the ability to roll thinner-walled, harder special steels, and rapid steel passage. The existing drive could not meet these technical requirements, and due to its age, it faced issues such as difficulty in spare parts supply. Therefore, Ansteel decided to replace the existing equipment, with the following requirements:

* It can use Profibus-DP bus communication control to seamlessly replace the original drive without the need for the customer to modify the program.

* Meet the dynamic speed drop requirements of the PQF continuous rolling mill, ensuring that speed accuracy, speed fluctuation, torque accuracy, and torque response all meet the requirements.

* The vector control without PG (tachometer) must meet the technical requirements for rolling steel, ensuring the continuity of production.

3. INVT Solution

After comprehensively evaluating product performance, on-site solutions, on-site service, and price, Ansteel ultimately chose to use the INVT GD880 multi-drive inverter to seamlessly replace the original product.

Considering it was the first time using a domestic product, INVT selected a model with an increased capacity to 1500kW heavy-duty, model GD880-56-2052-6, and configured three GD880-51-0720-6 power units in parallel.

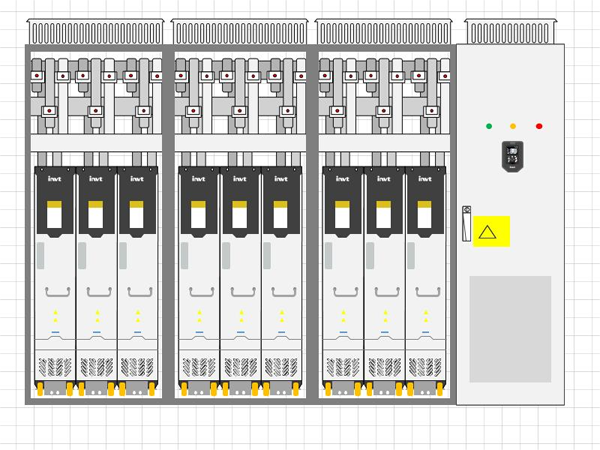

Cabinet Layout Diagram

4. Customer Benefits

* Through the free programming function of the GD880, it achieves a seamless replacement of imported brands without the need for users to modify the PLC program, making debugging quick and convenient.

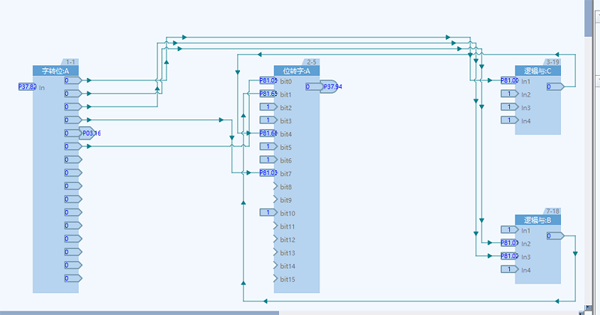

Free programming

* After the replacement, the system meets the dynamic speed drop requirements of the continuous rolling mill, ensuring stable speed and high-quality finished products. Not only can it roll special steels that the original brand could not handle, but it also satisfies the speed increase requirements after the upgrade of the 177 production line, thereby improving the production efficiency of the user's continuous rolling mill and achieving cost reduction and efficiency enhancement.

* It can perform steel passing with non-PG (no tachometer) vector control, ensuring stable control. This means that the system can continue running without stopping even if the encoder is damaged

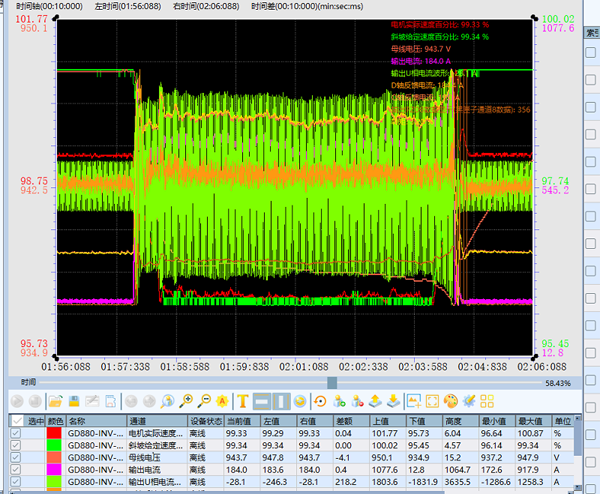

Control Waveform

a. Compared to the original brand, the drive cabinet size has been reduced while the power has increased. In the event of a fault, the system can run at a reduced capacity.

b. The power units are designed with quick-connect features, making maintenance convenient. Fault records are traceable

5. Conclusion

With the increasing maturity of domestic inverter technology and services, the trend towards domestic alternatives has become predominant in the steel industry. Relying on its own technological advantages and accumulated experience, INVT will continue to advance on the path of domestication, achieving breakthroughs in key projects for major customers such as Baowu and Ansteel. In the future, INVT will continue to strive forward, promoting the replication and dissemination of product solutions in the metallurgical industry, building a new model for digital business development, and assisting in the creation of new momentum for the metallurgical industry.

On-site Application Images

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.