AC 3PH 380…440VAC 3PH ±10%,-15%<1min 4~3000kW

AC 3PH 520…690VAC 3PH±10%,-15%<1min 55~6300kW

1. Flexible and easy to use

* Power unit modularization, facilitating integration.

* Comprehensive coverage of the power segment, while meeting the demand, saving the space layout in the cabinet

* The power module can be flexibly expanded to support seamless docking with third party PLC

* Professional debugging wizard to quickly complete drive configuration improving debugging efficiency.

* Programming can be modular and contigurable, reducing non-standard code development, ensuring firmware consistency.

facilitating spare parts management, and reducing maintenance costs.

* Open data flow diagram and transparent control scheme.

* Standard Ethernet debugging interface to achieve local remote debugging monitoring and maintenance of drive equipment.

2. Excellent performance

* Accuracy at stable speed:

- SVC:± 0.1%

- FVC:± 0.01%

* Torque accuracy

- FVC:≤3%,SVC:≤5%

* The multi-core architecture achieves high-speed and high-accuracy loop computing control, with good process consistency and

improved product quality for customers.

* Open loop zero,0HZ can output 150% torque,

*Master/slave control with millisecond-level response, achieving more balanced load distribution.

3. Highly reliable

* Selection of long lifetime components to ensure quality

from the source and stable running of equipment.

* Users can define 10 faults,so as to reduce unnecessary downtime and ensure continuous operation of equipment.

* The control unit is electrically isolated from the power unit to improve EMC performance

* Spare parts can be replaced efficiently and quickly in just 30 minutes, ensuring that the production process is accurate

4. Communication stability

* Support 24v auxiliary power supply to ensure that the communication is always online

* Communication redundancy Settings to improve the reliability of automation system process control

5. Easy to debug

* LCD screen with intuitive display, without the need to consult the operation manual, saving debugging time.

* Standard Ethernet debugging interface to achieve local and remote debugging, monitoring, and maintenance of drive equipment .

* Saving data to 10 channels, saving 100 aroups of faut waveform data cvclicall through re-writing, and analvzing faults without the need of fault simulation.

6. functional safety

* STO Safety torque off SIL3

7. Video

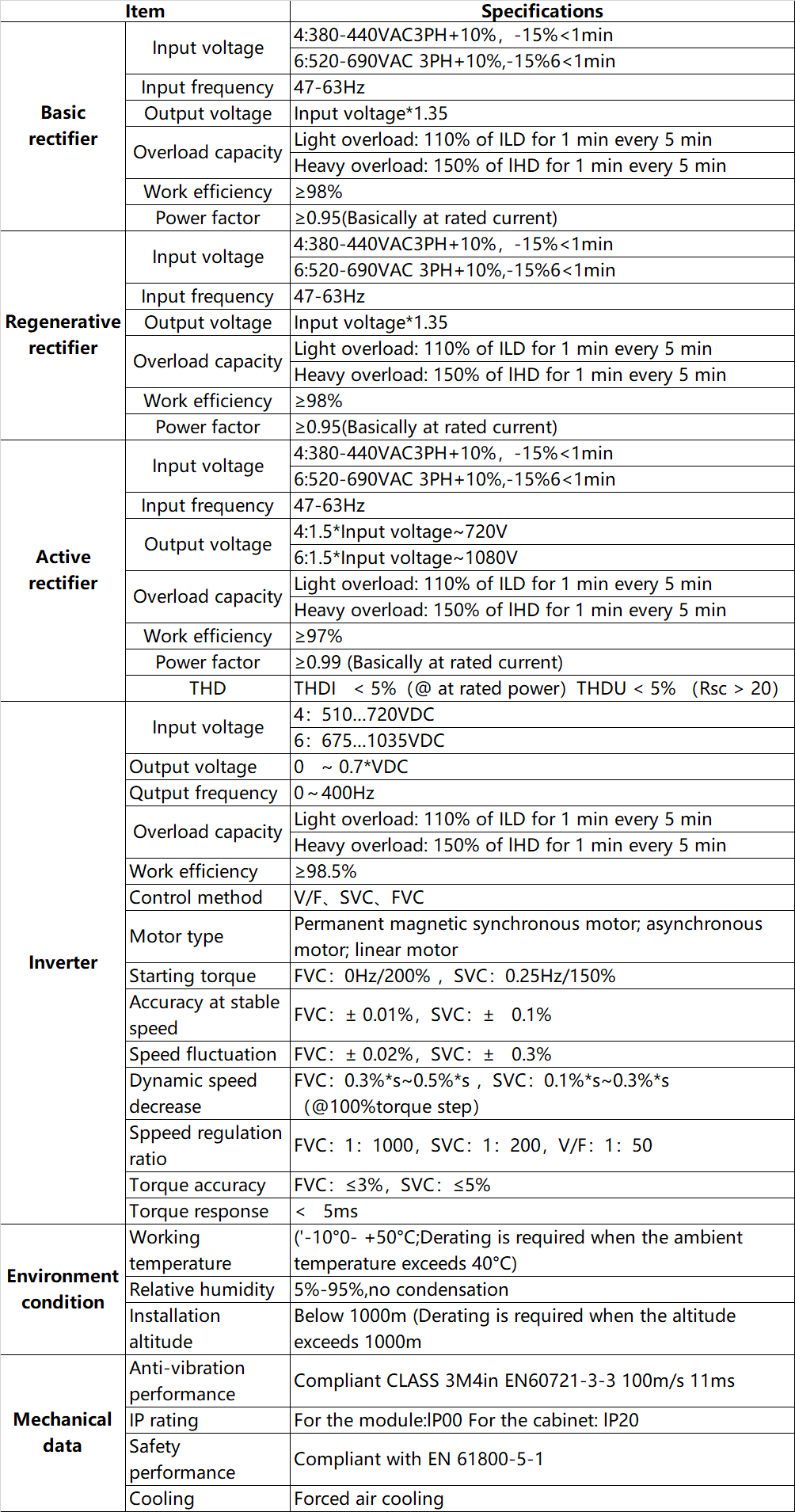

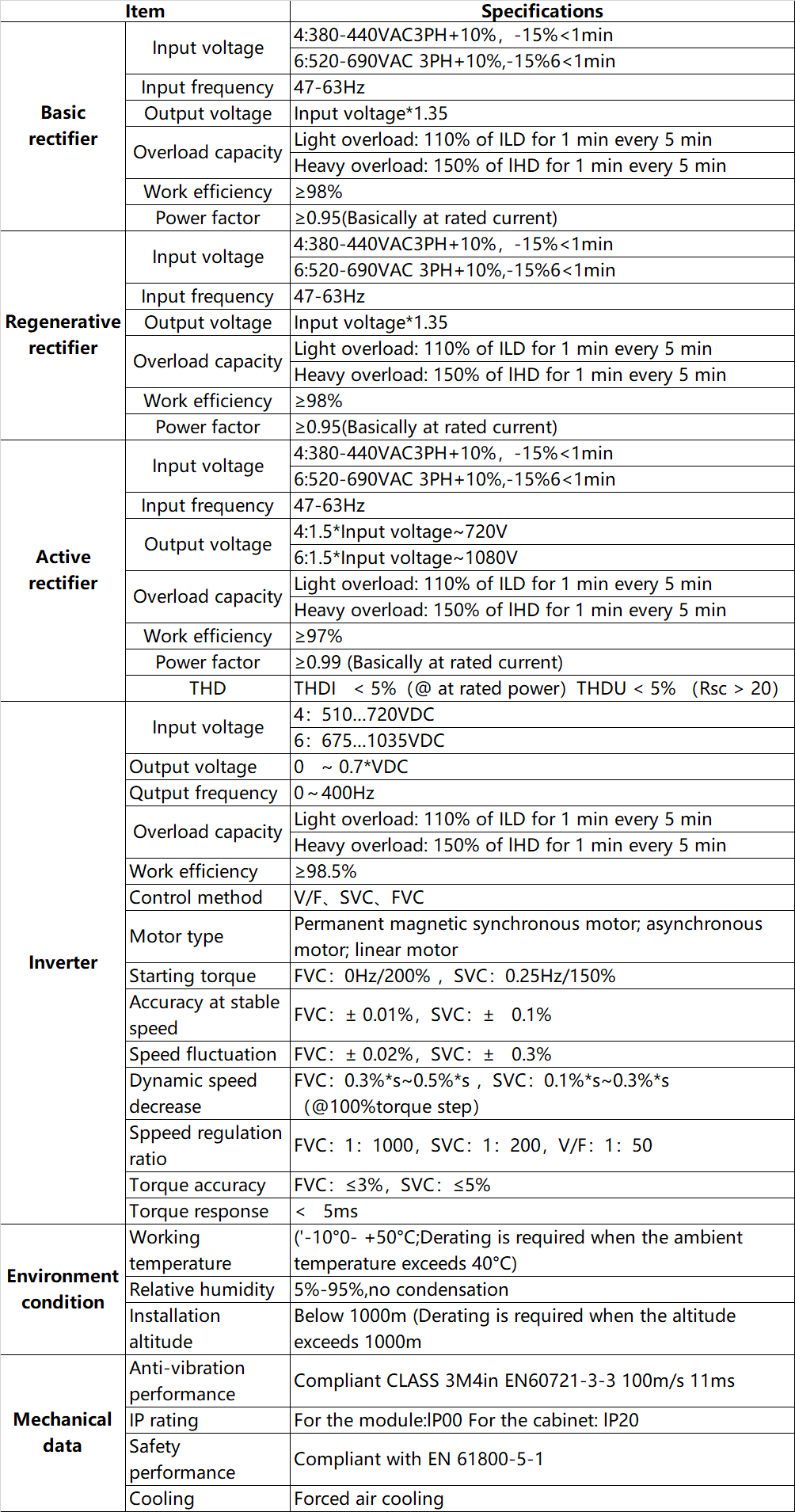

8. Specification:

INVT GD880 Engineering VFD for Petroleum Mud Pump

2024-06-18INVT GD880 VFD for Auxiliary Driving and Multi Driving Roller Conveyor in Medium Plate Mill

2024-07-09INVT GD880 Series VFD for Alumina Diaphragm Pumps Application

2024-09-24INVT GD880 VFD for Chemical Fiber Industry

2024-10-28INVT GD880 Series Engineering VFD for PQF Pipe Mill

2024-11-14INVT GD880 VFD for Aluminum Kneader Application

2024-12-17INVT GD880 Four-Quadrant VFD on A Hydraulic Motor Test Bench

2025-01-07INVT GD880 Drives Enhance Fixed-Length Cutting Performance for Heavy Plate Mills

2025-12-05

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.