1. Background

There are many types of production equipment in the chemical fiber industry, and the speed of the equipment needs to be adjusted according to different processes and production needs. The traditional speed regulation mode is usually realized through mechanical transmission or gear change, but this mode has problems such as large energy consumption and complex transmission system, and the application of frequency conversion speed regulation technology can solve these problems.

Previously, most of the mainstream VFDs in the chemical fiber industry were imported brands, but with the development of domestic VFDs technology, localization has become a major trend.

2. Process

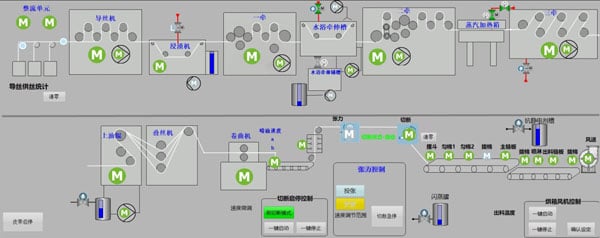

The main process flow for producing post-spun cotton-type yarn is as follows: The stored and bundled synthetic fiber materials pass through the guide wire machine to the impregnation machine for oil treatment. They are then drawn through the first traction unit to a water bath traction trough, followed by the second traction unit to a steam heating box for heating. After that, the fibers pass through the third traction unit to the oiling rollers for oil application. Once the oiling is complete, the three strands of yarn are bundled using a bundling machine. The bundled yarn is then wound onto rolls by a winding machine and cut it after passing through a tension frame.

3. Customer Issues

1. Inability to accurately monitor motor speed and position.

2. Zero speed control is not possible during shutdown, causes fibre filaments to be wasted at

the moment of stopping.

3. Complex system structure, poor maintainability and expandability.

4. There is a delay in data transmission and slow response.

5. There are harmonic effects.

4. INVT Solutions

Based on the customer's pain points, INVT recommended the GD880 series engineering drive inverters as a solution.

GD880 system: FVC, High torque at low frequency, High speed accuracy, PROFIBUS-DP bus control, High data real-time, good synchronisation of drive units, multi-drive solutions for public DC busbars, stabilisation of bus voltage, low energy consumption, optical fibre communication between control unit and power unit, separation of strong and weak current, improve the EMC performance of the complete system, high stability, input reactor with 6/12 pulse rectifier configuration,low system harmonics, high power factor, Energy-consumption braking,Enables quick stops at high speeds, etc.

5. Advantages

With INVT solutions, customers can achieve:

* Reducing Energy Consumption: the speed of the motor is changed according to the actual load condition, avoiding the energy loss of mechanical transmission and achieving the optimisation of energy consumption.

* Reliability and Stability: the speed of the motor is changed according to the actual load condition, the motor load is always optimised and equipment failures are predicted and prevented in advance by monitoring and adjusting the motor load in real time.

* Harmonic Suppression: reduce the possibility of motor power loss, heat, vibration, noise, resonance burn equipment.

* Precision and Efficiency: the use of PN bus control simplifies the system structure, reduces the number of devices and wires, strengthens the internal functions of field devices, reduces round-trip transmission of signals, and improves data real-time.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.