Abstract: This paper introduces the application of INVT IVC1L PLC in fully automatic napkin machine, which realizes a series of processes from material unwinding, folding, folding, channeling and paper sorting.

Keyword:INVT IVC1L Automatic napkin machine

Preface

Automatic napkin equipment is the equipment developed from the improvement of semi-automatic napkin equipment. Compared with the semi-automatic napkin machine, the automatic napkin equipment has increased the paper management mechanism. The original manual paper management efficiency is low and relatively unhygienic. The use of automatic paper management can greatly improve the production efficiency.

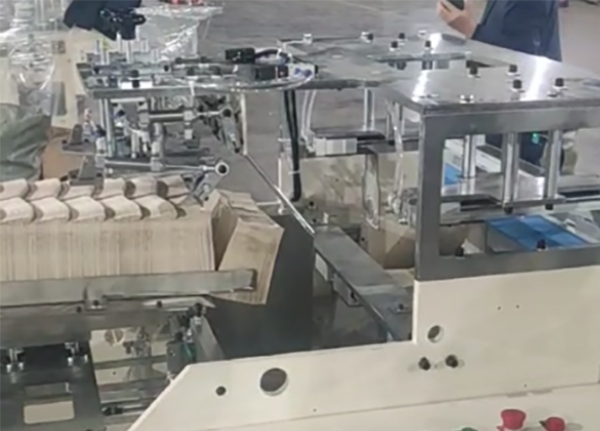

2 Mechanical Structure Introduction

The machinery can be divided into material unwinding, material embossing, folding mechanism, folding mechanism, cutting and dividing channel, folding mechanism, material handling mechanism, and paper discharge conveying according to the material flow.

1, Material unwinding: there are two ways of material unwinding, center unwinding and relying on pressure unwinding. The center unwinding generally uses special unwinding frequency control. By pressure unwinding can use frequency conversion to follow the master according to the speed ratio control. Also can follow the master through mechanical infinitely adjustable speed.

2, Material embossing: embossing the material can produce beautiful patterns, but also several sheets of paper can be meshed together, so that the paper is not easy to detach.

3, Folding mechanism: folding mechanism consists of a triangular folding board and a stepper motor. The embossed paper is folded into two layers after the triangle plate. The stepping motor drives a top rod, so that the position of the triangular plate can be raised and lowered to change, so that different stacks of paper produce a height difference, which is conducive to automatic folding later. There are two inductive proximity switches on the top bar, one at the origin and one at the limit. At the beginning of operation, the top bar returns to the home position, and then, with the operation of the main machine, the top bar follows the speed of the main machine and descends continuously. The system counts the number of folded pieces. When the set number of pieces is reached, the top bar quickly returns to the home position, and then continues to follow the mainframe down, and so on, to produce a split stack.

4, Folding mechanism: The folding mechanism consists of two folding rollers with three to four sets of clips on the folding rollers to fold the paper fed into it. After folding, the paper is pushed out of the folding mechanism by beating the claw. The perimeter of the folding rollers and the number of clips determine the length of the product paper. The main motor drives the folding rollers. An incremental encoder is mounted on one of the main motor's timing wheels. This encoder makes one revolution and the folded paper is folded exactly once. The system uses the encoder count to calculate the speed of the main machine and also to keep a count of the number of sheets folded. The stepper motor top lever and the running beat of the paper handling behind it follow the encoder.

5, Cutting and dividing: folded paper is zigzag together, through the cutter from the middle of the cut into a stack of one by one. Cutting knife is a band saw structure. Cutter has a manual sharpening device. The first use of the knife needs to open the edge.

6, Folding mechanism: The mechanism consists of counting paper blocking cylinder, folding paper blocking cylinder, taking paper rotating cylinder, folding lifting cylinder, folding lifting pushing cylinder. Equipment according to the master folding beat to run. The height difference of the stacked paper produced by the stepping top rod, counting paper blocking and folding paper blocking paper to separate the paper stack by stack.

7, The material handling mechanism: There must be a height difference to split the stack. After the paper is placed vertically, the paper is a bit tilted. Through the cylinder to the four sides of the paper stack to push pressure to make the paper upright vertical. The mechanism consists of side pushing cylinder, side pushing rotating cylinder, selective rotation pushing cylinder, finished product lifting cylinder, finished product pushing cylinder several institutions.

8, Paper dispensing mechanism: a conveyor belt is responsible for dispensing paper. The back of the napkin machine may have to be connected to the packaging mechanism. If the back-end equipment is blocked, it will stop the main machine. As the whole machine is running according to the beat, stopping the main machine does not affect the beat. The master machine stops, the conveyor belt will be suspended if it is running the state of the beat.

3 Solution

System configuration

| Model | Qty. | Brand | |

| PLC CPU | IVC1L-3624MAT | 1 | INVT |

| PLC module | IVC1L-2DA | 1 | INVT |

| HMI | VK2070-N0CXR | 1 | INVT |

| Inverter | GD20-1R5G-4 | 1 | INVT |

| Encoder | Incremental 2500ppr | 1 | Others |

| Stepper | Stepper | 1 | Others |

The control difficulty of this system lies in the control of the folding top bar and the split stack beat.

1, Folding top bar is driven by stepper motor, PLC sends pulse command to stepper driver to position and speed control the top bar.

The top bar has two action states, one is to quickly return to the origin, one is to follow the speed of the master down. The requirement of fast return is to rise from the lowest position to the home position within the time of stacking one sheet of paper. If you can't return to the home point within the time of stacking a sheet of paper, the division of the stack is not clear. There may be one will be divided in the

front pile, may also be in the back pile, resulting in the number of pieces is not accurate. Another state is to follow the master top bar down. PLC system counts the speed of the master through the encoder. And the time interruption is used to calculate the running speed of the master. The speed of the master is calculated and multiplied by the speed factor is the frequency of the top bar descent. There is also a proximity switch for the limit of the descent. If the descent process reaches the limit level it will not continue to descend.

2, Stacking system: The stacking device consists of several cylinders. The time of cylinder action in place is basically fixed. The time control is not good enough to ensure that the action matches the state of the master paper stacking. The system uses the stacking cycle method to set the action of each cylinder. This is expressed as start cycle and run cycle. For example, if 6 stacks per minute, one stack cycle is 10 seconds. The start of the cycle is calculated based on the timing of the opening of the stacking switch. For example, the start cycle is set to 0.05 cycle and the run cycle is 0.3 cycle for counting block paper. Meaning that the cycle to 0.5 seconds to start, to cycle 3 seconds cylinder solenoid valve power loss return. If the speed drops to 5 stacks per minute, a cycle is 20 seconds. Cycle to 1 second to start, to cycle 6 seconds cylinder solenoid valve power loss back.

4 Conclusion

This system is tested by customers for smooth operation at various speeds, and everything works well.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.