Abstract: INVT Products used IVC1L PLC 8no’s and DA200 servo. Rotary color printing machine on T-shirt pieces as per the setting done through HMI

Keywords: Multiple position and speed controlling in Axis controlling through pulse and direction.

1. Introduction

Rotary screen printing is a continuous method of printing in which a perforated cylindrical screen applies a colorant made from either pigment or dye. The colorant is forced from the interior of the cylindrical screen and onto the fabric. A special pump automatically feeds a paste inside the perforated cylinder (or spherical screen) and, as the screen rotates, a cylinder rolls over the fabric and dried at drying station..

* It has total 12 pcs of work station, 06pcs of printing work stations, 06 pcs of drying systems. The 06 printing head can be controlled independently.

* Machine can be adjustable pressure and speed of repeated overprint, suitable for various printing requirements.

Machine pneumatic control table version up and down, Electric control rotation and cylinder pasting color on the fabric through pneumatic cylinder, to achieve machine working speed.

Printing station

2. Project information and Solution

2.1 Project information :

* Automatic Screen Printing Machine:

This automatic 6 color 12 station automatic t-shirt silk screen printing machine is widly used in textile/garment screen printing industry, such as garments, T-shirts and sport cloths, bags, PVC and so on.

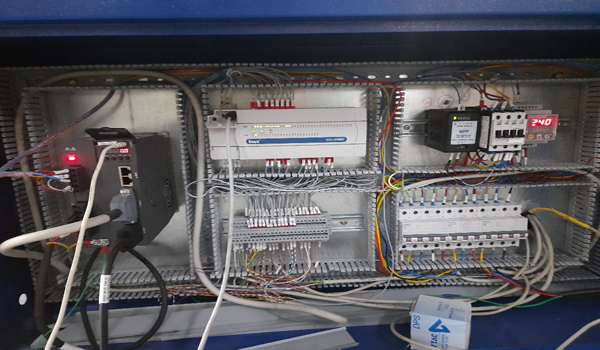

Rotary Table control Panel

* PLC mounting and wiring:

Pneumatic cylinders, induction motors, and local operating push buttons of each station controlled by the PLC installed at particular station.

2.2 INVT solution

S.NO | Product | Qty |

1 | SV DA200-011-4 | 1 |

2 | IVC11L PLC | 8 |

3. Advantages and benefits

• Servo Position is controlled by PLC, and values can be able to feed through HMI. Manually operational.

• Position accuracy/spins, speed are set by operator.

• Operational in single cycle, continuous cycle.

• With high speeds that can print up to 120 yards per minute, rotary screen printing’s production speed is incomparable.

• Surface treatments are compatible with rotary screen printing, which allows for unique creative capabilities.

• Rotary screen printing allows the application of additional components (such as glitter, adhesives, sequins, pearlescent, metallic, & 3D particles) to the fabric. (For reference, digital printing processes cannot apply surface treatments.)

4. Conclusion

All the PLC, HMI, VFD and servo are successfully used in this application, processes, and performance, accuracy and stability all meet the process requirement.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.