1. Background of the project

With the rapid development of economy and the improvement of people's living standard, the use of napkin is becoming more and more widespread. Automatic napkin machine as a large-scale production of napkins as an important tool, according to the material flow can be divided into the material unwinding, material embossing, folding mechanism, folding mechanism, cutting and channeling, folding mechanism, material handling mechanism, paper conveying and other production links, and the degree of automation and precision of the production process for the quality of the product and the production efficiency has a significant impact.

2. Customer needs

The customer is a company specializing in the production of high-quality tissue paper machinery, in order to improve production efficiency and product quality, the following requirements:

* High-speed cutting control and precise control: the controller realizes high-speed and accurate cutting of paper.

* Multi-functional operation: the controller realizes multiple operations, such as paper tapping and sweeping, paper positioning, paper cutting and stacking.

* Frequency converter can control the speed and direction of the motor, and ensure the stability and reliability of the system.

3. INVIT Solution

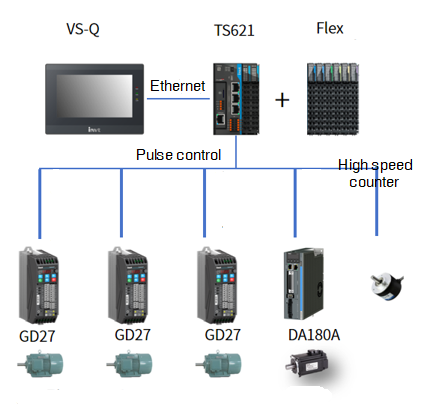

In order to meet the development needs of the fully automatic napkin machine, INVT provides a system solution of VS-Q series HMI + TS series PLC + FLEX expansion IO + GD27 inverter + DA180A servo to assist customers to improve production efficiency and product quality.

In this solution, INVT products effectively solve the control difficulties of servo depalletizing and palletizing beats.

* Through the high-speed counting input function of PLC, an incremental high-speed counter is connected to the input terminal, and the high-speed counter is connected to the main cutter 1:1, which realizes the detection of the speed and phase of the cutter. The palletizing system controls the trigger operation timing of each cylinder solenoid valve according to the phase.

* In order to improve the synchronization of the spindle and the cutter, the program uses the HDI port of the GD27 inverter to accept the pulse instruction from the PLC to adjust the speed, which is more anti-interference than the analog instruction and has higher precision.

* The top bar of depalletizing has two action states, one is to return to the origin quickly, and the other is to follow the speed of the host computer down. The fast return to the origin requires the servo to have strong response speed, and the response frequency of DA180A servo speed loop is as high as 2.5KHz, which can greatly improve the response speed of the system and maximize the performance of the machinery. Measurement of the top rod mechanism 10cm back to the original speed can be controlled within 65ms, to meet the requirements of the system.

4. Advantages of the solution

* High-efficiency production: The automated process can realize continuous production, with a single-pass efficiency of 30 packages/minute, which improves the efficiency by about 50% compared with the semi-automatic model and reduces the number of employees.

* High quality: INVT's controller can realize high-precision cutting and folding to ensure product quality.

* The electrical system uses a full set of solutions, which is easy for product maintenance and has stable performance and long life, with flexible topology and openness, which can be configured according to market demand to meet market segments.

5. Summary

INVT's solutions help customers realize the high production efficiency and high quality of fully automated napkin machines, as well as improve the efficiency and market competitiveness of the entire production line.

In addition to the above solutions, INVT also provides customized solutions for other processes in the printing and packaging industry, realizing automated production lines and helping enterprises achieve the goals of high efficiency, low cost and environmental protection.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.