With technological progress and increased market demand, it is expected that the future of household paper packaging equipment industry will continue to develop.

As the household paper industry continues to concentrate to the head, the industry competition will further intensify, the degree of industrial automation is getting higher and higher, for the high-end household paper equipment enterprises to provide a larger market space and development opportunities.

Breaking with tradition, innovative solutions

For the traditional semi-automatic packaging machine can not be automatic bagging problem, INVT and equipment manufacturers in-depth exchanges and communication, through the electrical and mechanical cooperation, the introduction of a set of automatic bagging solutions, to realize the semi-automatic to fully automatic change, greatly enhancing the operability of the packaging machine and the degree of automation.

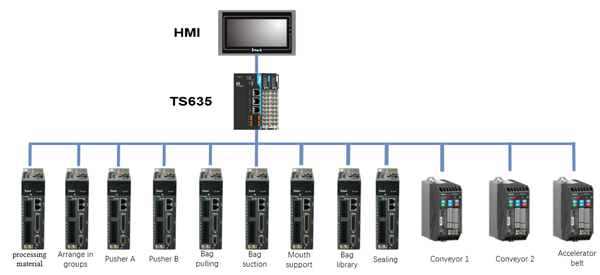

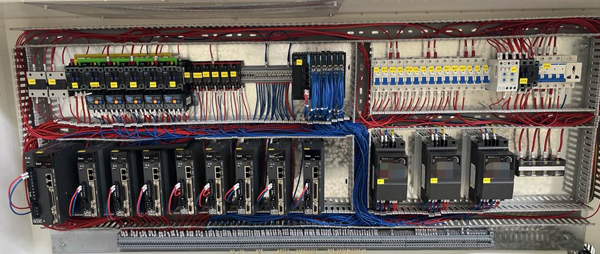

The program adopts HMI+TS635+DA180 complete set of INVT program. In terms of touch screen interaction, the system has built-in one-key back to the original, one-key reset, one-key start, data monitoring and other quick functions, which is convenient for operators to quickly operate and equipment maintenance personnel to quickly identify the problem. In addition, the entire equipment is controlled by IMS20B servo motors, which provides fast response, accurate positioning, improved production efficiency, and improved stability of packaged products.

Solution Topology Diagram

Diversification of functions in line with the times

The TS635, the main product of INVT, brings new applications to packaging equipment through its advantages.

1, Bag library, bag pulling, mouth support, bag suction, four-axis cooperation to complete the automatic bagging action, to solve the artificial bag location is not allowed, the efficiency is not high.

2, Sealing using servo replacement cylinder, according to the height of the product automatically adjust the sealing opening, to solve the mechanical adjustment of the size of the cumbersome. Product switching 1S to complete the order change, greatly reducing the time to adjust the machine.

3, Adopting EtherCAT bus control, solving the problem of pulse interference, ensuring the positioning accuracy and improving the response speed at the same time.

Continuous upgrading to help new breakthroughs

INVT system solution, through its excellent performance and flexible application successfully upgraded the packaging machine program to realize automatic feeding, automatic bagging and packaging production, providing users with more efficient and convenient solutions.

In the future, INVT will continue its independent research and development to bring all kinds of customized solutions to customers, replacing traditional technology with low consumption, low pollution and high efficiency, promoting the sustainable development of the industry, and helping customers achieve new breakthroughs.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.