In the warehouse workshop, conveying line is a common material conveying equipment, and its common types are belt conveying, roller conveying, etc., through a conveying line connected to form a continuous conveying chain, to complete the material conveying task.

Industry pain points

As the most common equipment for smart factories and smart logistics, the logistics conveyor line has a wide range of use, a large number, a long uninterrupted operation time, and high requirements for the stability of automation components.

2. In order to reduce costs, the number of on-site electric control cabinets is large, and the volume of automation components (PLC, VFD, remote IO) is required, and the installation density of a single electric control cabinet is increased and the number of electric control cabinets is reduced.

3. The number of on-site automation components is large, the workload of debugging and installation is large, time-consuming and error-prone, and the wiring is simple and the debugging is convenient.

INVT Solution

INVT provides flexible system solutions for logistics conveyor lines to meet the needs of the industry:

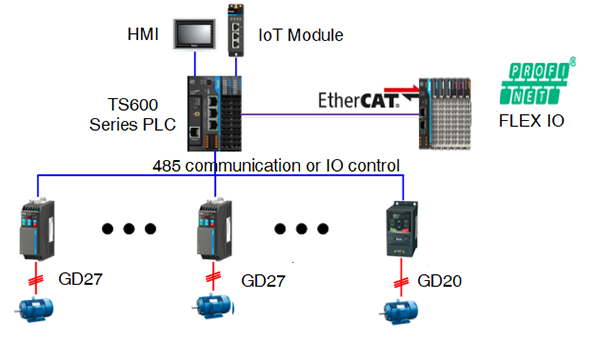

Solution 1: TS600 PLC EtherCAT communication, distributed control of the VFD of each section of the conveyor line through the remote I/O module, and the multi-section speed of the VFD is used to achieve stable positioning.

Solution 2: Adapt Profinet communication master PLC, and the VFD of each section of the conveyor line is distributed through the remote IO module, and the multi-stage speed of the VFD is used to achieve smooth positioning.

Solution Topology:

Features and value of the solution:

1, Provide a full set of automation components for PLC, HMI, remote IO, VFD, and Internet of Things terminals, with small size and increase the installation density of a single electric control cabinet.

2, The VFD is designed with heavy load, 150% overload for 1 minute, and the ambient temperature is 50°C without derating operation, which is compatible with asynchronous motors and permanent magnet synchronous motors, with excellent performance.

3, Remote IO can be adapted to Profinet, EtherCAT and other communications to meet a variety of bus requirements.

4, The use of pressure spring type quick-plug control terminal, free of wiring tools, improve wiring efficiency, in and out of the power line, to prevent the input and output from being reversed, and downloading parameters through the external keypad, so that the batch debugging is efficient and quick.

5, INVT logistics conveyor line system solution provides a full set of localized automation components to ensure the safety of the supply chain.

Shenzhen a well-known lithium company automated three-dimensional warehouse

Warehousing is one of the most important links in modern logistics management. Along with the use of new technologies such as Internet of Things (IoT) and robots, the warehouse management system has become more and more indispensable. Relying on mature and stable industrial automation products, INVT provides professional system solutions and reliable technical support for the intelligent upgrade of logistics conveyor lines, helping logistics enterprises quickly solve thorny problems and realize smart logistics.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.